Product Description

FAQ

Q:Is your company a trading company or a manufacturer?

A: We have our own factory.

Q:How long does the lead time take?

A: If the goods are in stock, it is generally 1-2 days; if the goods are not in stock, it is 5-10 days, depending on the quantity.

Q: Can I order shaft bore couplings that are not listed in the catalog?)(Additional machining service for coupling shaft hole

A:Of course.In addition, the recommended dimensional tolerance for the applicable shaft diameter is H7.

Q: How to handle when the received parts are of poor quality?

A:If there is any non-conformity of the product, please contact us immediately, we will check the problem in the first time, and rework or repair.

Q: Why choose XingHe Precision Transmission ?

A:As a professional manufacturer of coupling , we possess a skillful team of workers and designers To provide our customers with first-class services.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Roller Chain Couplings for Heavy Machinery and Industrial Conveyors

Yes, roller chain couplings are suitable for use in heavy machinery and industrial conveyors. They are widely used in various industrial applications, including mining equipment, steel mills, heavy-duty conveyors, and other heavy machinery systems.

The robust design of roller chain couplings allows them to handle high torque and heavy loads, making them ideal for demanding industrial environments. They are capable of transmitting significant power while providing flexibility to accommodate misalignments and shock loads.

Industrial conveyors often require reliable power transmission systems that can handle continuous operation and endure the harsh conditions of heavy material handling. Roller chain couplings offer a cost-effective and durable solution for connecting conveyor drive systems, enabling smooth and efficient operation.

When selecting roller chain couplings for heavy machinery or industrial conveyors, it is essential to consider the specific requirements of the application, including torque, speed, shaft size, and environmental conditions. Additionally, regular maintenance and proper lubrication are vital to ensure optimal performance and longevity of the coupling in these demanding applications.

Roller Chain Couplings in Applications Requiring Frequent Starts and Stops

Yes, roller chain couplings can be used in applications that require frequent starts and stops. These couplings are designed to provide reliable torque transmission and accommodate misalignments even during repetitive and rapid motion changes.

The key features that make roller chain couplings suitable for such applications include:

- Durable Construction: Roller chain couplings are typically constructed from high-quality materials, such as steel or stainless steel, which offer excellent durability and resistance to wear and fatigue.

- Shock Absorption: The flexible nature of roller chain couplings allows them to absorb shocks and vibrations that may occur during frequent starts and stops, preventing damage to connected equipment.

- Backlash Minimization: Roller chain couplings are designed to minimize backlash, which is the amount of free play between the connected shafts. This feature ensures precise and reliable torque transmission, even when starting and stopping repeatedly.

- Smooth Operation: The chain and sprocket design of roller chain couplings allows for smooth operation, reducing jarring movements during starts and stops.

- Misalignment Tolerance: Roller chain couplings can accommodate angular and parallel misalignments between shafts, which is essential in applications where frequent starts and stops may lead to slight shifts in the alignment.

- Easy Maintenance: Roller chain couplings are relatively easy to maintain, making them suitable for applications requiring frequent operation. Regular inspection and lubrication can help ensure optimal performance.

It is important to select the appropriate size and type of roller chain coupling based on the specific requirements of the application, including the expected frequency of starts and stops. Proper maintenance and monitoring of the coupling’s condition can help prolong its lifespan and ensure smooth operation even in demanding applications with frequent motion changes.

Working Principle of Roller Chain Coupling and Its Advantages

A roller chain coupling works on the principle of transferring torque between two shafts using a roller chain wrapped around sprockets on each shaft. The sprockets are connected by the roller chain, and when one sprocket rotates, it drives the other sprocket, transmitting the torque from one shaft to the other.

The advantages of roller chain couplings over other coupling types include:

- High Torque Capacity: Roller chain couplings can handle high torque loads, making them suitable for heavy-duty industrial applications.

- Compact Design: The compact and simple design of roller chain couplings allows for easy installation in tight spaces and restricted environments.

- Misalignment Tolerance: Roller chain couplings can accommodate angular, parallel, and axial misalignments between the shafts, reducing the need for precise alignment during installation.

- Shock Absorption: The inherent flexibility of the roller chain allows it to absorb shocks and dampen vibrations, protecting connected equipment from sudden loads and impacts.

- Cost-Effective: Roller chain couplings are generally cost-effective compared to other coupling types, providing an economical solution for power transmission needs.

- Wide Application Range: Roller chain couplings are used in various industries, including manufacturing, agriculture, construction, and material handling, due to their versatility and reliable performance.

- Easy Maintenance: Roller chain couplings are relatively easy to maintain and require minimal lubrication to keep the chain running smoothly.

- Long Service Life: When properly installed and maintained, roller chain couplings offer a long service life, contributing to the overall efficiency and reliability of mechanical systems.

Overall, the working principle and advantages of roller chain couplings make them a popular choice for transmitting torque between shafts in diverse industrial applications.

editor by CX 2024-02-19

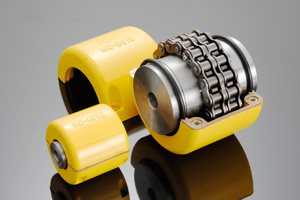

China Best Sales Roller Chain Coupling with Aluminum Cover and Sprockets

Product Description

Product Description

COUPLINGS

| HRC | FCL | Chain coupling | GE | L | NM | MH | Torque limiter |

| HRC 70B | FCL90 | KC4012 | GE14 | L050 | NM50 | MH45 | TL250-2 |

| HRC 70F | FCL100 | KC4014 | GE19 | L070 | NM67 | MH55 | TL250-1 |

| HRC 70H | FCL112 | KC4016 | GE24 | L075 | NM82 | MH65 | TL350-2 |

| HRC 90B | FCL125 | KC5014 | GE28 | L090 | NM97 | MH80 | TL350-1 |

| HRC 90F | FCL140 | KC5016 | GE38 | L095 | NM112 | MH90 | TL500-2 |

| HRC 90H | FCL160 | KC6018 | GE42 | L099 | NM128 | MH115 | TL500-1 |

| HRC 110B | FCL180 | KC6571 | GE48 | L100 | NM148 | MH130 | TL700-2 |

| HRC 110F | FCL200 | KC6571 | GE55 | L110 | NM168 | MH145 | TL700-1 |

| HRC 110H | FCL224 | KC8018 | GE65 | L150 | NM194 | MH175 | |

| HRC 130B | FCL250 | KC8571 | GE75 | L190 | NM214 | MH200 | |

| HRC 130F | FCL280 | KC8571 | GE90 | L225 | |||

| HRC 130H | FCL315 | KC1571 | |||||

| HRC 150B | FCL355 | KC12018 | |||||

| HRC 150F | FCL400 | KC12571 | |||||

| HRC 150H | FCL450 | ||||||

| HRC 180B | FCL560 | ||||||

| HRC 180F | FCL630 | ||||||

| HRC 180H | |||||||

| HRC 230B | |||||||

| HRC 230F | |||||||

| HRC 230H | |||||||

| HRC 280B | |||||||

| HRC 280F | |||||||

| HRC 280H |

Catalogue

Workshop

Lots of coupling in stock

FAQ

Q1: Are you trading company or manufacturer ?

A: We are factory.

Q2: How long is your delivery time and shipment?

1.Sample Lead-times: 10-20 days.

2.Production Lead-times: 30-45 days after order confirmed.

Q3: What is your advantages?

1. The most competitive price and good quality.

2. Perfect technical engineers give you the best support.

3. OEM is available.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Efficient Power Transmission and Low Maintenance of Roller Chain Couplings

Roller chain couplings offer efficient power transmission and low maintenance due to their unique design and construction:

- High Torque Capacity: Roller chain couplings are capable of transmitting high torque between the driving and driven shafts, making them suitable for heavy-duty applications.

- Reduced Power Loss: The flexible and rugged nature of roller chain couplings helps minimize power loss during torque transmission, ensuring energy efficiency in the system.

- Shock Absorption: Roller chain couplings can absorb shocks and vibrations, protecting connected machinery and components from damage and wear.

- Misalignment Tolerance: They can accommodate both angular and parallel misalignments, reducing stress on the shafts and extending the equipment’s life.

- Simple and Reliable Design: Roller chain couplings have a simple design with fewer moving parts, leading to low maintenance requirements and reduced downtime.

- Easy Installation: Their easy installation process allows for quick setup, minimizing installation time and associated costs.

- Durability and Longevity: Roller chain couplings are made from robust materials such as steel, ensuring durability and longevity even in harsh operating conditions.

- Cost-Effectiveness: Due to their long service life and low maintenance needs, roller chain couplings offer a cost-effective solution for power transmission applications.

Overall, roller chain couplings provide reliable and efficient power transmission while requiring minimal maintenance, making them a preferred choice in various industries where continuous operation and reduced downtime are essential.

Roller Chain Couplings in Applications Requiring Frequent Starts and Stops

Yes, roller chain couplings can be used in applications that require frequent starts and stops. These couplings are designed to provide reliable torque transmission and accommodate misalignments even during repetitive and rapid motion changes.

The key features that make roller chain couplings suitable for such applications include:

- Durable Construction: Roller chain couplings are typically constructed from high-quality materials, such as steel or stainless steel, which offer excellent durability and resistance to wear and fatigue.

- Shock Absorption: The flexible nature of roller chain couplings allows them to absorb shocks and vibrations that may occur during frequent starts and stops, preventing damage to connected equipment.

- Backlash Minimization: Roller chain couplings are designed to minimize backlash, which is the amount of free play between the connected shafts. This feature ensures precise and reliable torque transmission, even when starting and stopping repeatedly.

- Smooth Operation: The chain and sprocket design of roller chain couplings allows for smooth operation, reducing jarring movements during starts and stops.

- Misalignment Tolerance: Roller chain couplings can accommodate angular and parallel misalignments between shafts, which is essential in applications where frequent starts and stops may lead to slight shifts in the alignment.

- Easy Maintenance: Roller chain couplings are relatively easy to maintain, making them suitable for applications requiring frequent operation. Regular inspection and lubrication can help ensure optimal performance.

It is important to select the appropriate size and type of roller chain coupling based on the specific requirements of the application, including the expected frequency of starts and stops. Proper maintenance and monitoring of the coupling’s condition can help prolong its lifespan and ensure smooth operation even in demanding applications with frequent motion changes.

What is a Roller Chain Coupling and How Does It Function in Mechanical Power Transmission?

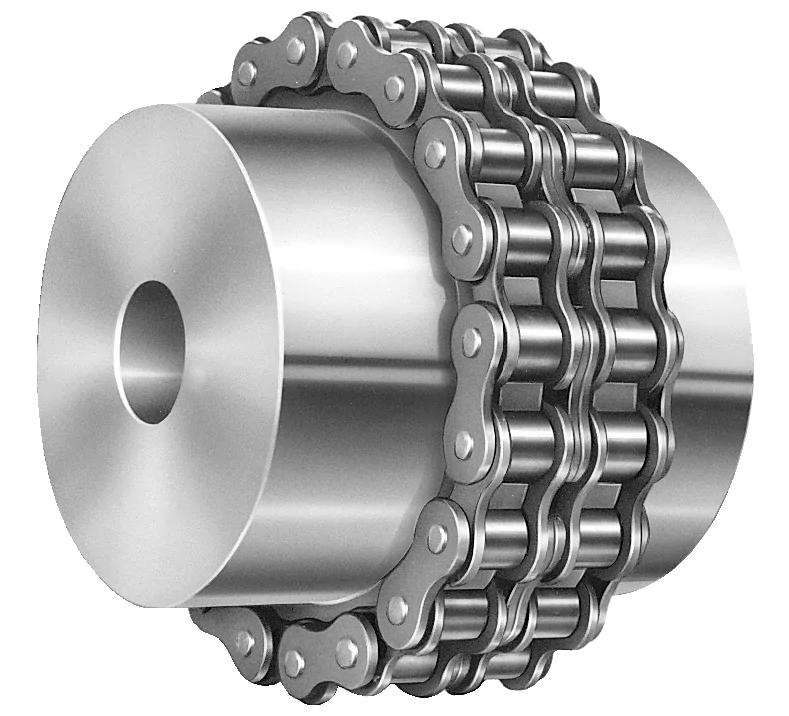

A roller chain coupling is a type of flexible coupling used in mechanical power transmission systems to connect two shafts and transmit torque between them. It consists of two sprockets, one on each shaft, and a roller chain that meshes with the sprockets.

The functioning of a roller chain coupling is as follows:

- Connection: The roller chain coupling is installed by placing the two sprockets on the respective shafts. The sprockets are positioned facing each other.

- Meshing: The roller chain is then looped around the sprockets, and its pins engage with the teeth of the sprockets.

- Power Transmission: When one shaft rotates, the roller chain transfers the rotational motion to the other shaft through the meshing of the chain with the sprockets.

- Torque Transfer: The torque is transmitted from one shaft to the other via the roller chain. This allows the two shafts to rotate together, providing a flexible and efficient power transmission connection.

Roller chain couplings are known for their reliability, simplicity, and ability to handle high torque loads. They are widely used in various industrial applications, including conveyor systems, pumps, mixers, and other equipment that require reliable torque transmission.

editor by CX 2024-01-19

China factory Kc 4012-10020 Sprocket Roller Chain Coupling for Alternator Sprockets Shaft Flexible Coupling

Product Description

Company Profile

HangZhou Xihu (West Lake) Dis. Mechanical Transmission Parts Co., Ltd. is a professional manufacturer of mechanical transmission parts, founded in 1987. Our company is committed to standard roller sprocket, single row and multi-row sprocket, non-standard sprocket, gear, rack, bevel gear, sprocket, shaft, gear shaft and other products. We have passed ISO 9001 .Xihu (West Lake) Dis. company has a number of experienced engineers, involved in plHangZhou, testing, heat treatment, inspection, the use of strict and accurate testing methods. Our sprockets are widely used in agricultural machinery, stereoscopic garage, mining equipment, woodworking machinery, petroleum machinery and other industries. Implementation standards such as ANSI.BS, DIN.KANA, etc., can also be customized according to the drawing processing

Our products have won wide praise and trust from customers for their excellent quality. HangZhou Xihu (West Lake) Dis. mechanical transmission Parts Co., Ltd. adhere to the quality of survival, innovation and development, customer first business philosophy, dedicated to domestic and foreign customers service. We warmly welcome you to negotiate business with us.

Product Description

| Standard or Nonstandard | Standard | Application | Maqchinery | |

| Hardness | Hardened Tooth Surface | Material | C45 | |

| Specification | Various Sprockets | Pitch(PCD) | 40.50.60.100 | |

| Toothed Portion Shape | Spur Gear | teeth | 10-100z | |

| HS Code | 84839000 | Production Capacity | 100000 Pcs/Year |

Detailed Photos

FAQ

1. Are you manufacturer or trade company ?

We are a manufacturing factory founded in 1987 ,with trade team for international service.

2. What terms of payment you usually use ?

T/T . 30% deposit ,and 70% before finish production .Price :FOB ZheJiang .

3. Can you make products according to customer”s design ?

Yes , we can make according to customer”s drawing and samples .OED and ODM are acceptable.

4.How long is your delivery time ?

Genarally it is 5-15 days afte rthe deposit .It will take more days customized.

5. What do I need for offering a quote ?

Please offer us 2D or 3d drawing (with material ,dimension,surface treatment and other technical datas etc.), quantity ,or samples .

Then we will quote the best price .

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Standard Sizes and Specifications of Roller Chain Couplings

Roller chain couplings come in various sizes and specifications to accommodate a wide range of mechanical power transmission applications. The standard sizes and specifications of roller chain couplings typically include:

- Chain Size: Roller chain couplings are available in different chain sizes, such as 40, 50, 60, 80, 100, etc. The chain size indicates the pitch of the roller chain used in the coupling.

- Torque Capacity: The torque capacity of a roller chain coupling varies based on its size and design. Manufacturers provide torque ratings that specify the maximum amount of torque the coupling can handle without failure.

- Speed Rating: Roller chain couplings have a maximum speed rating, which indicates the highest rotational speed at which the coupling can operate safely and efficiently.

- Material: Roller chain couplings are commonly made from materials such as carbon steel, stainless steel, or nickel-plated steel, providing different levels of strength, corrosion resistance, and durability.

- Hub Type: Roller chain couplings may come with different hub types, such as pilot bore hubs or taper bore hubs, to suit various shaft connections.

- Number of Teeth: Some roller chain couplings have specific tooth configurations that can affect their performance and backlash characteristics.

- Misalignment Capacity: Manufacturers specify the maximum allowable misalignment (angular and parallel) that the coupling can accommodate to ensure reliable operation.

It is essential to refer to the manufacturer’s catalogs or product specifications to determine the exact sizes and specifications available for specific roller chain couplings. Selecting the right size and specifications depends on the application’s requirements, including torque, speed, misalignment, and environmental conditions.

Handling Angular and Parallel Misalignments with Roller Chain Couplings

Yes, roller chain couplings are designed to accommodate both angular and parallel misalignments simultaneously. These couplings use a flexible roller chain to transmit torque between the driving and driven shafts, allowing for some degree of misalignment without causing undue stress on the coupling or connected equipment.

The roller chain’s flexible nature enables it to bend and twist slightly, accommodating small angular misalignments between the shafts. Additionally, the design of the sprockets and chain links allows for some axial movement, which addresses parallel misalignments.

It is important to note that while roller chain couplings can handle moderate misalignments, excessive misalignment should be avoided to prevent premature wear and potential coupling failure. Regular maintenance and alignment checks are crucial to ensure the coupling operates within its design limits and delivers reliable performance.

What is a Roller Chain Coupling and How Does It Function in Mechanical Power Transmission?

A roller chain coupling is a type of flexible coupling used in mechanical power transmission systems to connect two shafts and transmit torque between them. It consists of two sprockets, one on each shaft, and a roller chain that meshes with the sprockets.

The functioning of a roller chain coupling is as follows:

- Connection: The roller chain coupling is installed by placing the two sprockets on the respective shafts. The sprockets are positioned facing each other.

- Meshing: The roller chain is then looped around the sprockets, and its pins engage with the teeth of the sprockets.

- Power Transmission: When one shaft rotates, the roller chain transfers the rotational motion to the other shaft through the meshing of the chain with the sprockets.

- Torque Transfer: The torque is transmitted from one shaft to the other via the roller chain. This allows the two shafts to rotate together, providing a flexible and efficient power transmission connection.

Roller chain couplings are known for their reliability, simplicity, and ability to handle high torque loads. They are widely used in various industrial applications, including conveyor systems, pumps, mixers, and other equipment that require reliable torque transmission.

editor by CX 2024-01-16

China Hot selling Roller Chain Coupling with Aluminum Cover and Sprockets

Product Description

1.Chain used

sprocketes are manufactured with a tooth profile and dimensional precision to bring out the maximum performance of the chain you will use.

2. Number of teeth

sprockets are available with small and large numbers of teeth to match your usage conditions.

|

Single pitch sprocket |

Double pitch sprocket |

||||

|

*Chain matched:35(06C) /06BTeeth:from 9-120 *Chain matched:40(08A) /08BTeeth:from 9-120 *Chain matched:50(10A) /10BTeeth:from 9-120 *Chain matched:60(12A) /12BTeeth:from 9-120 *Chain matched:80(16A) /16B Teeth:from 9-120 *Chain matched:100(20A)/20B Teeth:from 9-120 *Chain matched:120(24A) /24B Teeth:from 9-120 *Chain matched:140(28A) /28B Teeth:from 9-120 *Chain matched:160(32A) /32B Teeth:from 9-120 *Chain matched:200(40A) /40B Teeth:from 9-120 |

*P=25.4mm Teeth:from 7-100

*P=31.8mm Teeth:from 7-100

*P=38.1mm Teeth:from 7-100

*P=50.8mm Teeth:from 7-100

*P=63.5mm Teeth:from 7-100 |

3. Consturction

4. Material

Carbon Steel, Stainless Steel,Aluminum, Nylon, POM, Copper, Brass,42CrMo,40Cr,A3 and so on.

5. Bore

Pilot bore, finished bore, taper bore, bearing hole and special bore

6. Treatment

Heat Treatment: Hardening and Tempering, High Frequency Quenching, Carburizing Quenching and so on.

Surface Treatment: Zinc Plating, Chrome plated, Black oxide Treatment, Spray Paint, Mirror Finish, Sand-blasting and so on.

FAQ

1. Are you manufacturer or trade company ?

We are a manufacturing factory founded in 1987 ,with trade team for international service.

2. What terms of payment you usually use ?

T/T . 30% deposit ,and 70% before finish production .Price :FOB ZheJiang .

3. Can you make products according to customer”s design ?

Yes , we can make according to customer”s drawing and samples .OED and ODM are acceptable.

4.How long is your delivery time ?

Genarally it is 5-15 days afte rthe deposit .It will take more days customized.

5. What do I need for offering a quote ?

Please offer us 2D or 3D drawing (with material ,dimension,surface treatment and other technical datas etc.), quantity ,or samples .

Then we will quote the best price .

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can chain couplings accommodate parallel misalignment?

Yes, chain couplings are designed to accommodate a certain degree of parallel misalignment between the connected shafts. Parallel misalignment refers to the situation where the axes of the two shafts are not perfectly aligned and run parallel to each other but at a distance.

Chain couplings have some inherent flexibility that allows them to tolerate a certain amount of parallel misalignment. The flexibility is primarily provided by the roller chain, which can compensate for small parallel displacements between the shafts. This flexibility helps to reduce stress on the coupling components and allows for smooth operation even in the presence of parallel misalignment.

However, it is important to note that chain couplings have limitations in terms of parallel misalignment. Excessive parallel misalignment beyond the specified limits can lead to increased stress, uneven load distribution, accelerated wear, and potential coupling failure. The manufacturer’s specifications and guidelines should be followed to ensure that the parallel misalignment remains within the acceptable range for the specific chain coupling being used.

Proper alignment during installation is crucial to minimize parallel misalignment. The shafts should be aligned as closely as possible to ensure optimal performance and longevity of the chain coupling and the connected machinery or equipment. In some cases, additional measures such as shims or adjustable mounts may be necessary to achieve the desired alignment.

Regular inspection and maintenance of the chain coupling are also important to identify and address any parallel misalignment issues that may arise over time. If significant parallel misalignment is detected, corrective measures should be taken to realign the shafts or consider alternative coupling options that are better suited for parallel misalignment requirements.

In summary, chain couplings can accommodate a certain degree of parallel misalignment, but excessive misalignment should be avoided. Proper alignment during installation and adherence to manufacturer’s guidelines are essential for ensuring optimal performance, reliability, and longevity of the chain coupling and the connected machinery or equipment.

How to install a chain coupling?

Proper installation of a chain coupling is crucial for ensuring its optimal performance and longevity. Here are the steps to follow when installing a chain coupling:

-

Prepare the Work Area: Before beginning the installation, ensure that the work area is clean and free from any debris or contaminants. This will help prevent any damage to the coupling components during installation.

-

Inspect the Components: Carefully inspect the chain coupling components, including the sprockets, roller chain, connecting pins, and bushings or bearings. Check for any signs of damage or wear. Replace any components that are worn or damaged.

-

Position the Coupling: Position the coupling on the shafts that need to be connected. Ensure that the shafts are aligned properly and the coupling is centered between them.

-

Install the Sprockets: Slide the sprockets onto the shafts, with the teeth facing each other. Make sure the sprockets are securely seated on the shafts and aligned with each other.

-

Connect the Roller Chain: Loop the roller chain around the sprockets, ensuring that it is properly engaged with the sprocket teeth. Connect the ends of the roller chain using the connecting pins. Insert the connecting pins through the pin holes in the chain links and secure them with retaining clips or other fasteners.

-

Tension the Chain: Adjust the tension of the roller chain to the manufacturer’s specifications. The chain should have the appropriate amount of slack to allow for smooth operation and accommodate misalignment but should not be too loose or too tight. Follow the manufacturer’s guidelines for determining the correct chain tension.

-

Secure the Bushings or Bearings: If the chain coupling uses bushings or bearings, ensure they are properly installed in the bores of the sprockets and provide a secure and smooth rotation of the shafts.

-

Apply Lubrication: Apply the recommended lubricant to the roller chain and sprockets. Proper lubrication is essential for reducing friction, wear, and noise, and it helps ensure smooth operation of the chain coupling.

-

Check Alignment and Rotation: Once the chain coupling is installed, check the alignment of the shafts and the rotation of the coupling. Verify that the coupling rotates smoothly without any binding or interference.

-

Inspect and Test: After installation, thoroughly inspect the entire chain coupling assembly. Look for any signs of misalignment, unusual noise, or vibration. Test the coupling’s operation by running the machinery at a low speed and gradually increasing to the normal operating speed. Monitor the coupling for any issues or abnormalities.

Following these installation steps will help ensure a proper and secure installation of the chain coupling, promoting efficient power transmission and minimizing the risk of premature failure or damage.

What are the advantages of using chain couplings?

-

Flexible and Reliable Connection: Chain couplings provide a flexible and reliable connection between rotating shafts. They can accommodate misalignment between the shafts, including angular, parallel, and axial misalignments. This flexibility helps to reduce stress on the shafts and bearings, resulting in smoother operation and extended equipment lifespan.

-

High Torque Capacity: Chain couplings are capable of transmitting high torque loads. The positive engagement between the sprocket teeth and the chain rollers allows for efficient power transfer, making them suitable for applications that require the transmission of substantial rotational forces.

-

Mechanical Protection: Chain couplings act as mechanical protection by providing a breakable link in the power transmission system. In case of sudden overloads or jams in the system, the chain can break, preventing damage to the machinery components. This feature helps to protect expensive equipment and minimizes downtime for repairs.

-

Misalignment Compensation: Chain couplings can compensate for misalignment between the connected shafts. They can tolerate angular misalignment, where the shafts are not perfectly aligned at an angle, parallel misalignment, where the shafts are offset from each other, and axial misalignment, which refers to displacement along the axis of the shafts. This ability to accommodate misalignment helps to prevent excessive stress and premature wear on the shafts and bearings.

-

Wide Range of Applications: Chain couplings are versatile and find applications in various industries and machinery. They are used in conveyors, pumps, crushers, mixers, industrial drives, and many other systems. The ability to handle different torque requirements, speed variations, and misalignment conditions makes chain couplings suitable for a wide range of power transmission needs.

-

Easy Maintenance: Chain couplings are relatively easy to maintain. Regular lubrication of the chain and sprockets helps to reduce friction and wear, ensuring smooth operation and extending the life of the coupling. Maintenance tasks such as chain tensioning and inspection can be carried out without requiring complex tools or specialized training.

In summary, the advantages of using chain couplings include their flexible and reliable connection, high torque capacity, ability to compensate for misalignment, mechanical protection, wide range of applications, and ease of maintenance. These features make chain couplings a preferred choice in various industries where efficient power transmission and reliable operation are vital.

editor by CX 2024-01-15

China Hot selling Kc 4012-10020 Sprocket Roller Chain Coupling for Alternator Sprockets Shaft Flexible Coupling

Product Description

Company Profile

HangZhou Xihu (West Lake) Dis. Mechanical Transmission Parts Co., Ltd. is a professional manufacturer of mechanical transmission parts, founded in 1987. Our company is committed to standard roller sprocket, single row and multi-row sprocket, non-standard sprocket, gear, rack, bevel gear, sprocket, shaft, gear shaft and other products. We have passed ISO 9001 .Xihu (West Lake) Dis. company has a number of experienced engineers, involved in plHangZhou, testing, heat treatment, inspection, the use of strict and accurate testing methods. Our sprockets are widely used in agricultural machinery, stereoscopic garage, mining equipment, woodworking machinery, petroleum machinery and other industries. Implementation standards such as ANSI.BS, DIN.KANA, etc., can also be customized according to the drawing processing

Our products have won wide praise and trust from customers for their excellent quality. HangZhou Xihu (West Lake) Dis. mechanical transmission Parts Co., Ltd. adhere to the quality of survival, innovation and development, customer first business philosophy, dedicated to domestic and foreign customers service. We warmly welcome you to negotiate business with us.

Product Description

| Standard or Nonstandard | Standard | Application | Maqchinery | |

| Hardness | Hardened Tooth Surface | Material | C45 | |

| Specification | Various Sprockets | Pitch(PCD) | 40.50.60.100 | |

| Toothed Portion Shape | Spur Gear | teeth | 10-100z | |

| HS Code | 84839000 | Production Capacity | 100000 Pcs/Year |

Detailed Photos

FAQ

1. Are you manufacturer or trade company ?

We are a manufacturing factory founded in 1987 ,with trade team for international service.

2. What terms of payment you usually use ?

T/T . 30% deposit ,and 70% before finish production .Price :FOB ZheJiang .

3. Can you make products according to customer”s design ?

Yes , we can make according to customer”s drawing and samples .OED and ODM are acceptable.

4.How long is your delivery time ?

Genarally it is 5-15 days afte rthe deposit .It will take more days customized.

5. What do I need for offering a quote ?

Please offer us 2D or 3d drawing (with material ,dimension,surface treatment and other technical datas etc.), quantity ,or samples .

Then we will quote the best price .

Comparison of Roller Chain Couplings to Other Coupling Types

Roller chain couplings offer distinct advantages and characteristics that set them apart from other coupling types, such as gear or disc couplings. Below is a comparison of roller chain couplings with these two commonly used coupling types:

- Roller Chain Couplings:

– Roller chain couplings are flexible and can accommodate misalignments, making them ideal for applications where shafts may not be perfectly aligned.

– They offer good shock absorption, which is beneficial in systems with varying loads or frequent starts and stops.

– Roller chain couplings are relatively compact and lightweight compared to other couplings, making them suitable for space-constrained installations.

– These couplings are cost-effective and provide a reliable and efficient power transmission solution.

- Gear Couplings:

– Gear couplings are capable of handling high torque and can transmit power efficiently, making them suitable for heavy-duty applications.

– They have a high level of torsional rigidity, ensuring accurate torque transmission without backlash.

– Gear couplings are generally more expensive than roller chain couplings.

– They require accurate alignment during installation, which can be challenging in some applications.

- Disc Couplings:

– Disc couplings offer high torque capacity and torsional stiffness, providing precise torque transmission and no backlash.

– They have a compact design and are often used in applications with limited space.

– Disc couplings can handle misalignment to some extent but may not be as forgiving as roller chain couplings.

– They are generally more expensive than roller chain couplings.

When choosing the appropriate coupling type, it is essential to consider the specific requirements of the application, such as torque, misalignment, speed, space limitations, and budget constraints. Each coupling type has its strengths, and the selection should be based on the demands of the mechanical power transmission system.

Maintenance Requirements for Roller Chain Couplings

To ensure the optimal performance and longevity of roller chain couplings, regular maintenance is essential. Here are some key maintenance requirements:

- Lubrication: Regularly lubricate the roller chain and sprockets to reduce friction and wear. Use the appropriate lubricant recommended by the coupling manufacturer.

- Inspections: Periodically inspect the coupling for signs of wear, misalignment, or damage. Look for elongation or wear of the roller chain, damaged sprocket teeth, or any signs of excessive vibration.

- Tightening: Check and ensure that all fasteners, such as bolts and set screws, are properly tightened to the manufacturer’s recommended torque specifications.

- Alignment: Maintain proper alignment between the driving and driven shafts to prevent undue stress on the coupling components.

- Cleanliness: Keep the coupling and surrounding area clean and free from debris or contaminants that could interfere with its operation.

- Temperature: Avoid operating the coupling beyond its recommended temperature limits, as excessive heat can lead to premature failure.

- Replacement: Replace any worn or damaged components promptly to prevent further damage to the coupling or connected equipment.

Regular maintenance not only ensures the coupling’s optimal performance but also helps identify potential issues early, allowing for timely repairs or replacements. It is crucial to follow the manufacturer’s maintenance guidelines and schedule to ensure the coupling’s reliability and prevent unexpected failures that could disrupt operations and lead to costly downtime.

What is a Roller Chain Coupling and How Does It Function in Mechanical Power Transmission?

A roller chain coupling is a type of flexible coupling used in mechanical power transmission systems to connect two shafts and transmit torque between them. It consists of two sprockets, one on each shaft, and a roller chain that meshes with the sprockets.

The functioning of a roller chain coupling is as follows:

- Connection: The roller chain coupling is installed by placing the two sprockets on the respective shafts. The sprockets are positioned facing each other.

- Meshing: The roller chain is then looped around the sprockets, and its pins engage with the teeth of the sprockets.

- Power Transmission: When one shaft rotates, the roller chain transfers the rotational motion to the other shaft through the meshing of the chain with the sprockets.

- Torque Transfer: The torque is transmitted from one shaft to the other via the roller chain. This allows the two shafts to rotate together, providing a flexible and efficient power transmission connection.

Roller chain couplings are known for their reliability, simplicity, and ability to handle high torque loads. They are widely used in various industrial applications, including conveyor systems, pumps, mixers, and other equipment that require reliable torque transmission.

editor by CX 2023-12-13

China Good quality Machinery Part Roller Chain Coupling Aluminum Case with Sprockets Shaft Flexible Coupling Kc 4012-10020

Product Description

Product Description

The roller chain coupling is a flexible coupling of amazingly simple construction. It consists of a combination of 1 coupling chain and a pair of coupling sprockets. Flexible and strong, the roller chain coupling is suitable for a wide range of coupling applications.

Roller chain coupling can used for the environment which with high temperature, wet and dirty conditions. It is not suitable for the occasion which is in high speed and with strong impact load. Roller chain coupling should working with excellent lubrication and protection cover conditions.

The common chain coupling includes double roller chain coupling, single row roller chain coupling, tooth shape chain coupling, nylon chain coupling. Its scale is compact and its weight is light. But roller chain coupling don’t have high requirement to installation precision.

Generally speaking, it is usually in long service life. Production line equipment for various kinds of frozen food and dehydrated vegetables should transport by stainless steel chain. Roller chains are widely applied to household, industrial and agricultural machinery, includes conveyor, drawing machine, printing machine, automobile, motorcycle and bicycle.

Main Features

1.Simple structure,easy assembly and disassembly.

2.Light weight,and long service life.

3.Have a certain ability to compensate for installation less precision.

4.Suitable for high temperature,wet and dusty industrial environment.

5.Can not for high speed,violent vibration.

Techncial Date

| KASIN No. | Chain Type | d | L | G | S | D | H | C | Weight/Kg | A | B | Casing Weight/Kg | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3012 | 06B-2 × 12 | 12~16 | 64.8 | 29.8 | 5.2 | 35 | 45 | 10.2 | 0.31 | 69 | 63 | 0.22 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4012 | 40-2 × 12 | 12~22 | 79.4 | 36 | 7.4 | 35 | 62 | 14.4 | 0.73 | 77 | 72 | 0.3 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4014 | 40-2 × 14 | 12~28 | 79.4 | 36 | 7.4 | 43 | 69 | 14.4 | 1.12 | 84 | 75 | 0.31 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4016 | 40-2 × 16 | 14~32 | 87.4 | 40 | 7.4 | 50 | 77 | 14.4 | 1.5 | 92 | 72 | 0.35 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5014 | 50-2 × 14 | 15~35 | 99.7 | 45 | 9.7 | 55 | 86 | 18.1 | 2.15 | 101 | 85 | 0.47 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5016 | 50-2 × 16 | 16~40 | 99.7 | 45 | 9.7 | 62 | 93 | 18.1 | 2.75 | 110 | 87 | 0.5 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5018 | 50-2 × 18 | 16~45 | 99.7 | 45 | 9.7 | 70 | 106 | 18.1 | 3.6 | 122 | 85 | 0.6 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6018 | 60-2 × 18 | 20~56 | 123.5 | 56 | 11.5 | 85 | 127 | 22.8 | 6.55 | 147 | 105 | 1.2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6571 | 60-2 × 20 | 20~60 | 123.5 | 56 | 11.5 | 1/8822 0571 -57152031 Fax: 86~/8822 0571 -57152030

Can chain couplings transmit both torque and linear motion?No, chain couplings are primarily designed to transmit torque between rotating shafts and are not intended for transmitting linear motion. The main function of a chain coupling is to connect two shafts in order to transfer rotational power from one shaft to another. Chain couplings achieve torque transmission through the engagement of the roller chain with the sprockets on the connected shafts. As the driving sprocket rotates, it imparts rotational motion to the chain, which in turn rotates the driven sprocket connected to the other shaft. This mechanism allows the torque to be transmitted from one shaft to the other. However, chain couplings do not provide a means for converting or transmitting linear motion. They are not designed to handle axial displacement or linear forces. Attempting to use a chain coupling for transmitting linear motion would result in inefficient and unreliable operation, as the coupling is not designed to handle the specific requirements and forces associated with linear motion. For applications that require the transmission of linear motion, there are other types of couplings specifically designed for this purpose. Examples include rack and pinion systems, linear couplings, or specialized linear motion couplings that incorporate mechanisms such as ball screws or lead screws. These couplings are designed to convert rotary motion into linear motion or to transmit linear forces directly. It is important to select the appropriate coupling type based on the specific requirements of the application, whether it involves torque transmission or the transmission of linear motion. Consulting the manufacturer’s specifications, guidelines, or seeking expert advice can help ensure the correct coupling selection for a particular application.

What are the maintenance requirements for chain couplings?Maintaining chain couplings is essential for their reliable and efficient operation over time. Regular maintenance helps prevent premature wear, reduces the risk of unexpected failures, and prolongs the lifespan of the coupling. Here are some key maintenance requirements for chain couplings:

By following these maintenance requirements, you can ensure the optimal performance, longevity, and reliability of your chain coupling. Regular maintenance minimizes the risk of unexpected downtime, reduces repair costs, and maximizes the efficiency of your machinery or equipment.

How does a chain coupling work?A chain coupling works by connecting two rotating shafts using a roller chain and sprockets. The sprockets have teeth that engage with the rollers of the chain, creating a positive drive mechanism. When the first shaft rotates, it drives the sprocket attached to it. The engaged chain then transfers the motion to the second sprocket and the second shaft, causing it to rotate as well. The chain coupling design allows for flexibility and misalignment compensation. In the presence of angular misalignment between the shafts, the chain can accommodate the deviation by flexing and adjusting its position on the sprockets. Similarly, if there is parallel misalignment or axial displacement, the chain coupling can flex and adjust to maintain proper engagement and transmit torque between the shafts. The engagement between the sprocket teeth and the chain rollers ensures a positive drive, meaning that the torque from the driving shaft is efficiently transferred to the driven shaft. This makes chain couplings suitable for applications where high torque loads need to be transmitted. Proper lubrication is essential for the smooth operation and longevity of a chain coupling. Lubricants such as oil or grease are applied to the chain and sprockets to reduce friction and wear. The lubrication helps prevent heat buildup and ensures the chain and sprockets rotate smoothly, minimizing power losses and extending the lifespan of the coupling. In summary, a chain coupling operates by using a roller chain and sprockets to connect two rotating shafts. The engaged chain transfers torque from the driving shaft to the driven shaft, while accommodating misalignment between the shafts. The positive drive mechanism and the flexibility of the chain make chain couplings effective in transmitting high torque loads while allowing for smooth and reliable power transmission.

China Custom Machinery Part Roller Chain Coupling Aluminum Case with Sprockets Shaft Flexible Coupling Kc 4012-10020Product Description

Product Description The roller chain coupling is a flexible coupling of amazingly simple construction. It consists of a combination of 1 coupling chain and a pair of coupling sprockets. Flexible and strong, the roller chain coupling is suitable for a wide range of coupling applications. Main Features Techncial Date

|