Product Description

Product Description

We are offering a wide range of Chain Coupling to our respected clients. Our offered products are used to join 2 pieces of rotating equipment while permitting the various degree of misalignment or end movement or both. Moreover, by careful installation and maintenance of couplings, substantial savings can be made in reduced downtime and maintenance costs.

Packaging & Shipping

Company Profile

FAQ

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Roller Chain Couplings for Heavy Machinery and Industrial Conveyors

Yes, roller chain couplings are suitable for use in heavy machinery and industrial conveyors. They are widely used in various industrial applications, including mining equipment, steel mills, heavy-duty conveyors, and other heavy machinery systems.

The robust design of roller chain couplings allows them to handle high torque and heavy loads, making them ideal for demanding industrial environments. They are capable of transmitting significant power while providing flexibility to accommodate misalignments and shock loads.

Industrial conveyors often require reliable power transmission systems that can handle continuous operation and endure the harsh conditions of heavy material handling. Roller chain couplings offer a cost-effective and durable solution for connecting conveyor drive systems, enabling smooth and efficient operation.

When selecting roller chain couplings for heavy machinery or industrial conveyors, it is essential to consider the specific requirements of the application, including torque, speed, shaft size, and environmental conditions. Additionally, regular maintenance and proper lubrication are vital to ensure optimal performance and longevity of the coupling in these demanding applications.

Maintenance Requirements for Roller Chain Couplings

To ensure the optimal performance and longevity of roller chain couplings, regular maintenance is essential. Here are some key maintenance requirements:

- Lubrication: Regularly lubricate the roller chain and sprockets to reduce friction and wear. Use the appropriate lubricant recommended by the coupling manufacturer.

- Inspections: Periodically inspect the coupling for signs of wear, misalignment, or damage. Look for elongation or wear of the roller chain, damaged sprocket teeth, or any signs of excessive vibration.

- Tightening: Check and ensure that all fasteners, such as bolts and set screws, are properly tightened to the manufacturer’s recommended torque specifications.

- Alignment: Maintain proper alignment between the driving and driven shafts to prevent undue stress on the coupling components.

- Cleanliness: Keep the coupling and surrounding area clean and free from debris or contaminants that could interfere with its operation.

- Temperature: Avoid operating the coupling beyond its recommended temperature limits, as excessive heat can lead to premature failure.

- Replacement: Replace any worn or damaged components promptly to prevent further damage to the coupling or connected equipment.

Regular maintenance not only ensures the coupling’s optimal performance but also helps identify potential issues early, allowing for timely repairs or replacements. It is crucial to follow the manufacturer’s maintenance guidelines and schedule to ensure the coupling’s reliability and prevent unexpected failures that could disrupt operations and lead to costly downtime.

How to Select the Right Roller Chain Coupling for Specific Machinery or Equipment?

Selecting the right roller chain coupling for specific machinery or equipment involves considering several important factors. Here’s a step-by-step guide:

- Torque Requirements: Determine the torque that the coupling needs to transmit between the driving and driven shafts. This will help you choose a coupling with the appropriate torque capacity for your application.

- Speed: Consider the operating speed of the machinery. Higher speeds may require special high-speed roller chain couplings designed to handle the centrifugal forces.

- Misalignment: Evaluate the degree of misalignment between the shafts. Different roller chain couplings have varying misalignment capabilities, so choose one that can accommodate the misalignment in your application.

- Space Constraints: Measure the available space for the coupling. Some roller chain couplings are compact and may be suitable for applications with limited space.

- Environmental Conditions: Take into account the operating environment, including temperature, humidity, and exposure to contaminants. Choose a coupling material and finish that can withstand the environmental conditions.

- Load Characteristics: Assess the nature of the loads and any shock or vibration present in the system. For heavy-duty or shock-loaded applications, consider using heavy-duty roller chain couplings.

- Alignment Maintenance: Evaluate the ease of alignment maintenance. Some couplings may require more frequent checks and adjustments to maintain proper alignment.

- Backlash: Determine the level of backlash permissible in the application. Certain couplings may introduce minimal backlash, which is critical in precision systems.

- Cost: Consider the overall cost, including the initial purchase price and long-term maintenance expenses. Opt for a roller chain coupling that provides the best value for your specific needs.

By carefully considering these factors, engineers and designers can identify the most suitable roller chain coupling that ensures reliable and efficient power transmission for their machinery or equipment.

editor by CX 2024-05-17

China best Kc Roller Chain Shaft Coupling Sprocket Connector Flexible Couplings for Paper Bag Machine Gl with Housing Gear

Product Description

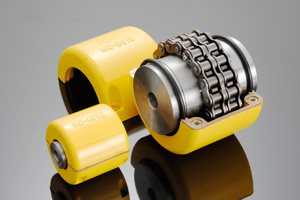

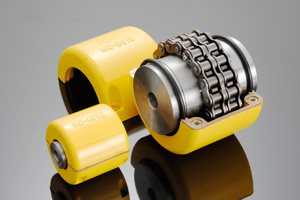

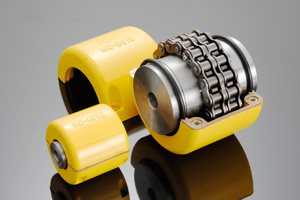

Kc Roller Chain Shaft Coupling Sprocket Connector Flexible Couplings for Paper Bag Machine Gl with Housing Gear

The chain coupling,compose of two-strand roller chains and 2 sprockets,features simple and compact structure,and high flexibility,power transmission capability and durability.What’s more,the chain coupling allows simple connection/disconnection,and the use of the housing enhances safety and durability.

Related products:

Production workshop:

Company information:

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Can chain couplings be used in high-speed applications?

Chain couplings can be used in certain high-speed applications, but there are limitations and considerations that need to be taken into account. The suitability of chain couplings for high-speed applications depends on factors such as the specific design of the coupling, the chosen chain type, and the operating conditions. Here are some key points to consider:

- Coupling Design: The design of the chain coupling plays a crucial role in determining its suitability for high-speed applications. High-speed chain couplings typically incorporate features that minimize vibration, reduce stress concentrations, and ensure smooth operation. Couplings designed for high-speed use may have additional balancing or damping mechanisms to counteract potential issues associated with centrifugal forces and resonance.

- Chain Type: The type of chain used in the coupling can affect its performance at high speeds. In general, roller chains are commonly used in chain couplings. However, for high-speed applications, special high-speed roller chains or other chain types designed for increased rotational speeds may be required. These chains are designed to minimize friction, reduce wear, and handle the centrifugal forces associated with high-speed operation.

- Bearing Selection: Proper bearing selection is critical for high-speed chain couplings. The bearings used in the coupling should be capable of handling the anticipated speeds and dynamic loads. High-quality, precision bearings with appropriate lubrication are typically necessary to ensure smooth operation and minimize the risk of premature failure.

- Balancing and Vibration: High-speed chain couplings should be properly balanced to minimize vibration and ensure stable operation. Imbalances in rotating components can lead to increased noise, excessive stress, and reduced service life. Balancing techniques such as dynamic balancing or the use of counterweights may be employed to achieve smooth and reliable operation.

- Lubrication: Adequate lubrication is crucial for high-speed chain couplings to minimize friction, reduce wear, and dissipate heat effectively. Proper lubrication practices, including the use of high-quality lubricants and regular maintenance, should be followed to ensure optimal performance and prevent premature failure.

Despite these considerations, it’s important to note that chain couplings may have practical limitations in terms of maximum allowable speeds. The specific speed limitations will depend on factors such as the coupling design, chain type, size, and the operating conditions. It is advisable to consult the manufacturer’s specifications and guidelines to determine the maximum recommended speed for a particular chain coupling.

In certain high-speed applications where chain couplings may not be suitable, alternative coupling types such as flexible disc couplings, gear couplings, or elastomeric couplings specifically designed for high-speed applications may be more appropriate. These couplings are engineered to handle the challenges associated with high rotational speeds, offering improved balance, reduced vibration, and higher speed capabilities.

Overall, when considering the use of chain couplings in high-speed applications, it is essential to carefully evaluate the specific requirements, consult with the manufacturer, and ensure that the coupling is designed and selected to operate safely and reliably at the desired speeds.

Can chain couplings accommodate angular misalignment?

Yes, chain couplings are designed to accommodate a certain degree of angular misalignment between the connected shafts. Angular misalignment refers to the situation where the axes of the two shafts are not perfectly aligned and form an angle with each other.

Chain couplings are flexible in nature, and their design allows for some degree of angular displacement. The flexibility is primarily provided by the roller chain, which can bend and adjust to a certain extent to accommodate the misalignment. This flexibility helps to reduce the stress on the coupling components and allows for smoother operation even in the presence of angular misalignment.

However, it is important to note that chain couplings have limitations in terms of angular misalignment. Excessive angular misalignment beyond the specified limits can lead to increased stress, accelerated wear, and potential coupling failure. The manufacturer’s specifications and guidelines should be followed to ensure that the angular misalignment remains within the acceptable range for the specific chain coupling being used.

Regular inspection and maintenance of the chain coupling are also essential to identify and address any misalignment issues. If significant angular misalignment is detected, corrective measures should be taken, such as realigning the shafts or considering alternative coupling options that are better suited for the specific misalignment requirements.

It is worth mentioning that chain couplings are more tolerant of angular misalignment compared to some other types of couplings, such as rigid or gear couplings. However, it is still important to strive for proper alignment during installation and minimize any excessive misalignment to ensure optimal performance, reliability, and longevity of the chain coupling and the connected machinery or equipment.

What is a chain coupling?

A chain coupling is a mechanical device used to connect two rotating shafts in a power transmission system. It consists of two sprockets or toothed wheels and a roller chain that meshes with the sprocket teeth. The sprockets are mounted on the respective shafts and linked together by the chain, allowing torque to be transmitted from one shaft to the other.

Chain couplings are designed to provide a flexible and reliable connection between shafts while accommodating misalignment between them. They are known for their ability to compensate for angular, parallel, and axial misalignments, making them suitable for a wide range of industrial applications.

The sprockets of a chain coupling typically have hardened teeth that engage with the rollers of the chain. The chain itself is made up of a series of interconnected links, each consisting of two plates joined by pins. The rollers are mounted on the pins, allowing them to rotate freely and mesh with the sprocket teeth.

One of the key advantages of chain couplings is their ability to transmit high torque loads. The engagement between the sprockets and the chain provides a positive drive, allowing for efficient power transfer even in demanding applications. Chain couplings are commonly used in heavy-duty machinery and equipment where large amounts of power need to be transferred, such as conveyors, mixers, crushers, and industrial drives.

Chain couplings also offer flexibility in shaft alignment. They can compensate for angular misalignment, which occurs when the shafts are not perfectly aligned at an angle. Additionally, they can accommodate parallel misalignment, where the shafts are offset from each other, as well as axial misalignment, which refers to the displacement along the axis of the shafts.

Proper lubrication is essential for the efficient operation and longevity of chain couplings. Lubricants such as oil or grease are applied to the chain and sprockets to reduce friction and wear. This helps to prevent heat buildup and ensures smooth rotation and power transmission.

Chain couplings are available in various sizes, configurations, and materials to suit different application requirements. The selection of a chain coupling depends on factors such as torque capacity, speed, shaft diameter, and misalignment tolerance.

In summary, chain couplings provide a flexible, reliable, and high-torque solution for connecting rotating shafts in power transmission systems. They offer the ability to compensate for misalignment, making them suitable for a wide range of industrial applications where efficient power transfer is crucial.

editor by CX 2024-02-24

China Best Sales CHINAMFG Customized Roller Chain Coupling, Chain Coupling for Chain Mortising Machine

Product Description

Densen customized roller chain coupling,chain coupling for chain mortising machine

We have professionals to solve your questions, please contact us directly!

| Product Name | Densen customized roller chain coupling,chain coupling for chain mortising machine |

| DN mm | 16~190mm |

| Rated Torque | 40~25000 N·m |

| Allowable speed | 4500~200 kN·m |

| Material | 45#steel |

| Application | Widely used in metallurgy, mining, engineering and other fields. |

Product show

Company Information

Equipment

Application Case

Typical case of diaphragm coupling applied to variable frequency speed control equipment

JMB type coupling is applied to HangZhou Oilfield Thermal Power Plant

According to the requirements of HangZhou Electric Power Corporation, HangZhou Oilfield Thermal Power Plant should dynamically adjust the power generation according to the load of the power grid and market demand, and carry out the transformation of the frequency converter and the suction fan. The motor was originally a 1600KW, 730RPM non-frequency variable speed motor matched by HangZhou Motor Factory. The speed control mode after changing the frequency is manual control. Press the button speed to increase 10RPM or drop 10RPM. The coupling is still the original elastic decoupling coupling, and the elastic de-coupling coupling after frequency conversion is frequently damaged, which directly affects the normal power generation.

It is found through analysis that in the process of frequency conversion speed regulation, the pin of the coupling can not bear the inertia of the speed regulation process (the diameter of the fan impeller is 3.3 meters) and is cut off, which has great damage to the motor and the fan.

Later, they switched to the JMB460 double-diaphragm wheel-type coupling of our factory (patent number: ZL.99246247.9). After 1 hour of destructive experiment and more than 1 year of operation test, the equipment is running very well, and there is no Replace the diaphragm. 12 units have been rebuilt and the operation is in good condition.

Other Application Case

Spare parts

Packaging & Shipping

Contact us

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

Roller Chain Couplings for Heavy Machinery and Industrial Conveyors

Yes, roller chain couplings are suitable for use in heavy machinery and industrial conveyors. They are widely used in various industrial applications, including mining equipment, steel mills, heavy-duty conveyors, and other heavy machinery systems.

The robust design of roller chain couplings allows them to handle high torque and heavy loads, making them ideal for demanding industrial environments. They are capable of transmitting significant power while providing flexibility to accommodate misalignments and shock loads.

Industrial conveyors often require reliable power transmission systems that can handle continuous operation and endure the harsh conditions of heavy material handling. Roller chain couplings offer a cost-effective and durable solution for connecting conveyor drive systems, enabling smooth and efficient operation.

When selecting roller chain couplings for heavy machinery or industrial conveyors, it is essential to consider the specific requirements of the application, including torque, speed, shaft size, and environmental conditions. Additionally, regular maintenance and proper lubrication are vital to ensure optimal performance and longevity of the coupling in these demanding applications.

Handling Angular and Parallel Misalignments with Roller Chain Couplings

Yes, roller chain couplings are designed to accommodate both angular and parallel misalignments simultaneously. These couplings use a flexible roller chain to transmit torque between the driving and driven shafts, allowing for some degree of misalignment without causing undue stress on the coupling or connected equipment.

The roller chain’s flexible nature enables it to bend and twist slightly, accommodating small angular misalignments between the shafts. Additionally, the design of the sprockets and chain links allows for some axial movement, which addresses parallel misalignments.

It is important to note that while roller chain couplings can handle moderate misalignments, excessive misalignment should be avoided to prevent premature wear and potential coupling failure. Regular maintenance and alignment checks are crucial to ensure the coupling operates within its design limits and delivers reliable performance.

Key Design Considerations for Roller Chain Couplings in Power Transmission Systems

When using roller chain couplings in power transmission systems, several key design considerations should be taken into account:

- Torque and Power Ratings: Calculate the required torque and power ratings to ensure the roller chain coupling can handle the expected loads and prevent overloading.

- Speed: Consider the operating speed of the coupling to select a roller chain and sprocket combination that can handle the rotational speed without experiencing excessive wear or fatigue.

- Shaft Sizes: Ensure that the roller chain coupling’s sprockets are compatible with the shaft sizes of the connected equipment. Proper fit is crucial to transmit torque effectively and prevent slippage.

- Misalignment: Assess the potential misalignments between the shafts and choose a roller chain coupling that can accommodate the expected angular, parallel, and axial misalignments to reduce stress on the system.

- Service Environment: Consider the operating conditions, such as temperature, humidity, and exposure to contaminants, and select roller chain coupling materials that can withstand the environmental factors for extended service life.

- Lubrication: Determine the lubrication requirements of the roller chain coupling and establish a maintenance schedule to ensure proper lubrication and prevent premature wear.

- Space Limitations: Take into account any spatial restrictions or limitations in the installation area to select a roller chain coupling that fits within the available space.

- Alignment Maintenance: Plan for periodic alignment checks and adjustments to maintain the optimal performance of the roller chain coupling and extend its service life.

- Cost: Evaluate the budget constraints and compare the cost of different roller chain coupling options to choose the most cost-effective solution without compromising performance.

By considering these design factors, engineers can ensure that the roller chain coupling performs optimally and provides reliable power transmission in their specific power transmission systems.

editor by CX 2024-02-20

China Best Sales CHINAMFG Customized Roller Chain Coupling, Chain Coupling for Chain Mortising Machine

Product Description

Densen customized roller chain coupling,chain coupling for chain mortising machine

We have professionals to solve your questions, please contact us directly!

| Product Name | Densen customized roller chain coupling,chain coupling for chain mortising machine |

| DN mm | 16~190mm |

| Rated Torque | 40~25000 N·m |

| Allowable speed | 4500~200 kN·m |

| Material | 45#steel |

| Application | Widely used in metallurgy, mining, engineering and other fields. |

Product show

Company Information

Equipment

Application Case

Typical case of diaphragm coupling applied to variable frequency speed control equipment

JMB type coupling is applied to HangZhou Oilfield Thermal Power Plant

According to the requirements of HangZhou Electric Power Corporation, HangZhou Oilfield Thermal Power Plant should dynamically adjust the power generation according to the load of the power grid and market demand, and carry out the transformation of the frequency converter and the suction fan. The motor was originally a 1600KW, 730RPM non-frequency variable speed motor matched by HangZhou Motor Factory. The speed control mode after changing the frequency is manual control. Press the button speed to increase 10RPM or drop 10RPM. The coupling is still the original elastic decoupling coupling, and the elastic de-coupling coupling after frequency conversion is frequently damaged, which directly affects the normal power generation.

It is found through analysis that in the process of frequency conversion speed regulation, the pin of the coupling can not bear the inertia of the speed regulation process (the diameter of the fan impeller is 3.3 meters) and is cut off, which has great damage to the motor and the fan.

Later, they switched to the JMB460 double-diaphragm wheel-type coupling of our factory (patent number: ZL.99246247.9). After 1 hour of destructive experiment and more than 1 year of operation test, the equipment is running very well, and there is no Replace the diaphragm. 12 units have been rebuilt and the operation is in good condition.

Other Application Case

Spare parts

Packaging & Shipping

Contact us

What are the common materials used in chain couplings?

Chain couplings are commonly made from various materials that offer the necessary strength, durability, and wear resistance required for transmitting torque between shafts. The choice of materials depends on factors such as the application requirements, operating conditions, and the specific design of the coupling. Here are some common materials used in chain couplings:

- Steel: Steel is one of the most widely used materials for chain couplings. It offers excellent strength, toughness, and resistance to wear and fatigue. Carbon steel and alloy steel are commonly used, with alloy steel providing enhanced properties such as higher tensile strength and improved corrosion resistance.

- Stainless Steel: Stainless steel is chosen for chain couplings when corrosion resistance is a critical requirement. It offers good mechanical properties along with resistance to rust and corrosion, making it suitable for applications in harsh environments or where exposure to moisture or chemicals is present.

- Cast Iron: Cast iron is occasionally used for chain couplings, particularly in applications where cost-effectiveness and moderate strength are important factors. Cast iron provides good wear resistance and can withstand moderate loads and operating conditions.

- Bronze: Bronze is utilized in certain specialized chain couplings, especially in applications where self-lubrication and high resistance to corrosion are required. Bronze has good friction properties and can operate in conditions where lubrication may be limited or unavailable.

- Plastics: In some cases, certain plastics, such as nylon or polyurethane, are used for chain coupling components like chain guides or protective covers. Plastics offer low friction, noise reduction, and resistance to chemicals, making them suitable for specific applications.

It’s important to note that the materials used in chain couplings may vary depending on the specific manufacturer, coupling design, and application requirements. It is recommended to consult the manufacturer’s specifications and guidelines to determine the appropriate materials for a particular chain coupling.

Additionally, in some cases, chain couplings may incorporate a combination of different materials, such as steel for the sprockets and roller chain, and elastomers for the flexible elements. This hybrid construction allows for optimized performance, balancing strength, flexibility, and damping characteristics.

Overall, the selection of materials for chain couplings is crucial to ensure reliable and efficient power transmission while considering factors such as load capacity, operating conditions, and the desired service life of the coupling.

What is the maximum torque capacity of a chain coupling?

The maximum torque capacity of a chain coupling can vary depending on several factors, including the size and design of the coupling, the type and quality of the components used, and the application requirements. It is important to refer to the manufacturer’s specifications and guidelines for the specific chain coupling being used. These specifications typically provide the maximum torque capacity or the maximum allowable torque for the coupling.

The maximum torque capacity is usually expressed in torque units, such as Newton-meters (Nm) or foot-pounds (ft-lb). It represents the maximum amount of torque that the chain coupling can transmit without exceeding its design limits or risking premature failure.

When selecting a chain coupling, it is crucial to consider the torque requirements of the application and choose a coupling with a sufficient torque capacity. Factors such as the power requirements, operating conditions, and misalignment tolerance should be taken into account to ensure that the selected coupling can handle the required torque.

It is important to note that exceeding the maximum torque capacity of a chain coupling can lead to various issues, including accelerated wear, excessive stress on the components, and potential coupling failure. Therefore, it is recommended to always operate the chain coupling within its specified torque limits to maintain its reliability and longevity.

For accurate and precise information regarding the maximum torque capacity of a specific chain coupling, it is necessary to consult the manufacturer’s documentation or contact the manufacturer directly. They can provide detailed information based on the specific design and specifications of the coupling.

What are the different types of chain couplings available?

Chain couplings come in various designs and configurations to suit different application requirements. Here are some common types of chain couplings:

- Standard Roller Chain Couplings: These are the most basic and widely used type of chain couplings. They consist of two sprockets connected by a roller chain. The sprockets have hardened teeth that engage with the chain rollers, providing a reliable power transmission. Standard roller chain couplings are generally suitable for applications with moderate torque and speed requirements.

- Double Roller Chain Couplings: Double roller chain couplings are similar to standard roller chain couplings but feature two parallel roller chains instead of one. This design increases the torque capacity and allows for higher power transmission. Double roller chain couplings are often used in applications that require higher torque and increased load-bearing capabilities.

- Silent Chain Couplings: Silent chain couplings, also known as inverted-tooth chain couplings, use a special toothed chain with a meshing sprocket design. The teeth of the chain engage with the sprocket grooves, providing a smooth and quiet operation. Silent chain couplings are commonly used in applications where noise reduction is important, such as precision machinery or equipment operating in noise-sensitive environments.

- Heavy-Duty Chain Couplings: Heavy-duty chain couplings are designed for applications that demand robust and rugged performance. They are constructed with larger sprockets and heavy-duty roller chains to handle high torque and heavy loads. These couplings are commonly used in industries such as mining, steel, and paper manufacturing, where extreme operating conditions and heavy machinery are present.

- Flexible Chain Couplings: Flexible chain couplings incorporate an elastomeric element, such as a rubber or polyurethane insert, between the sprockets and the chain. This element provides flexibility, damping, and some degree of misalignment compensation. Flexible chain couplings are suitable for applications that require shock absorption, vibration damping, and moderate misalignment tolerance.

- Stainless Steel Chain Couplings: Stainless steel chain couplings are specifically designed for applications that require corrosion resistance and sanitation, such as food processing, pharmaceutical, and chemical industries. They are made of stainless steel or other non-corrosive materials to withstand harsh environments and maintain hygienic conditions.

These are just a few examples of the different types of chain couplings available. Each type has its own advantages and is suitable for specific application requirements. It is important to carefully consider the torque, speed, misalignment, environmental factors, and other application-specific needs when selecting the appropriate chain coupling type for your particular application.

editor by CX 2023-12-14

China supplier Plastic Roller Chain (POM +SS 304) 40p for Conveyor Machine

Product Description

Small Pitch Roller Chains

Type: PC 35, PC 40, PC50, PC60

Materials: POM+ stainless steel

Pitch: 6.35mm, 9.525mm, 12.7mm, 15.875mm, 19.05mm

Color: White

We are manufacturer professionally in plastic top chains, stainless steel top chains, and other conveyor components. We have abtained the quality certificate of ISO 9001: 2000, and our products have been sold to Europe, Middle East, America and many other coutries and regions.

| type | PC 35, PC 40, PC50, PC60 |

| Materials | POM+ stainless steel |

| Pitch | 6.35mm, 9.525mm, 12.7mm, 15.875mm, 19.05mm |

Small Pitch Roller Chains

Type: PC 35, PC 40, PC50, PC60

Materials: POM+ stainless steel

Pitch: 6.35mm, 9.525mm, 12.7mm, 15.875mm, 19.05mm

Color: White

Advantages: short pitch, low noise, light weight,

corrosion resistance, diamagnetic.

Plasic roller chains can be widely use for eletronic, food,medicine, chemical industry etc.

We are manufacturer professionally in plastic top chains, stainless steel top chains, and other conveyor components. We have abtained the quality certificate of ISO 9001: 2000, and our products have been sold to Europe, Middle East, America and many other coutries and regions.

Our products application:

Packaging and conveying industry

Beverage bottling and handling industry

Food and meat processing industry

Chemical industry

Pharmaceuticals industry

Automobile industry

Electrical and electronics industry

Textile industry

Light engineering industry

| Material: | Plastic |

|---|---|

| Structure: | Roller Chain |

| Surface Treatment: | No |

| Chain Size: | 12.7mm |

| Feature: | Wear Resistant |

| Advantage: | Corrosion Resistance |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the maintenance intervals for roller chains?

Maintenance intervals for roller chains can vary depending on several factors, including the specific application, operating conditions, and manufacturer’s recommendations. Here’s a detailed answer to the question:

1. Lubrication: Proper lubrication is essential for the smooth operation and longevity of a roller chain. Lubrication intervals depend on the type of lubricant used, the chain’s speed, and the operating conditions. In general, it is recommended to lubricate the chain every 200-300 miles or as specified by the motorcycle manufacturer.

2. Tension Adjustment: Chain tension should be checked regularly and adjusted as needed to maintain optimal performance. Over time, roller chains can elongate due to wear, which affects their tension. It is recommended to check the chain tension every 500-1,000 miles or as advised by the motorcycle manufacturer.

3. Inspection: Regular visual inspection of the roller chain is important to identify any signs of wear, damage, or misalignment. Inspect the chain for loose or missing rollers, damaged links, excessive wear on sprockets, and any signs of rust or corrosion. Inspections should be performed at least every 500-1,000 miles or as recommended by the motorcycle manufacturer.

4. Cleaning: Periodic cleaning of the roller chain helps remove dirt, debris, and accumulated grime that can interfere with its performance. Cleaning intervals depend on the riding conditions and the level of contamination. Generally, it is advisable to clean the chain every 1,000-2,000 miles or when it appears visibly dirty.

5. Replacement: Roller chains have a finite lifespan and will eventually require replacement. The replacement interval depends on various factors, including the chain’s quality, usage conditions, and maintenance practices. As a general guideline, roller chains should be replaced when they become excessively worn, elongated beyond the manufacturer’s specifications, or show signs of damage that compromise their integrity.

It’s important to note that the maintenance intervals provided here are general guidelines, and it is crucial to refer to the motorcycle manufacturer’s specific recommendations for the roller chain used in your motorcycle. Adhering to the manufacturer’s guidelines and performing regular maintenance can help ensure the roller chain’s optimal performance, reliability, and longevity.

How do roller chains handle lateral loads?

Roller chains are primarily designed to handle axial loads, which are loads acting in the direction of the chain’s axis. However, roller chains can also tolerate a certain degree of lateral loads, which are loads acting perpendicular to the chain’s axis. Here’s a detailed answer to the question:

1. Sprocket Alignment: Proper sprocket alignment is crucial for roller chains to effectively handle lateral loads. The sprockets must be aligned in a parallel and concentric manner to ensure that the chain tracks properly and experiences minimal lateral force. Misaligned sprockets can cause the chain to derail or experience excessive wear due to uneven loading.

2. Tolerance for Lateral Misalignment: Roller chains have some tolerance for lateral misalignment between the sprockets. This means that the chain can tolerate a slight deviation from a perfectly straight line between the sprockets. The chain’s side plates and rollers are designed to provide some flexibility, allowing the chain to adjust to minor lateral forces without significant problems.

3. Guide Rails or Flanges: In applications where lateral loads are more significant, guide rails or flanges can be employed to help keep the roller chain aligned and prevent excessive lateral movement. These additional components act as guides and help control the chain’s lateral displacement, ensuring that it remains on the sprockets and operates smoothly.

4. Chain Tension: Proper chain tension is crucial for handling lateral loads. A well-tensioned chain minimizes slack and reduces the chances of lateral movement. It helps keep the chain engaged with the sprockets and ensures that the load is evenly distributed across the chain’s width.

It’s important to note that roller chains have a primary function of transmitting power and handling axial loads. While they can handle some lateral loads within their design limits, excessive lateral forces can lead to chain derailment, increased wear, and reduced performance. Therefore, it’s essential to design the system properly, consider the anticipated lateral loads, and ensure proper alignment and tension to maintain the chain’s integrity and performance.

Can roller chains be used for vertical lifting applications?

Yes, roller chains can be used for vertical lifting applications in certain circumstances. However, it is important to consider various factors to ensure safe and efficient operation. Here’s a detailed answer to the question:

Roller chains are primarily designed for transmitting power and motion in horizontal or slightly inclined applications. When used for vertical lifting, additional considerations must be taken into account:

1. Load Capacity: Roller chains have a rated load capacity that indicates the maximum weight they can safely lift. It is crucial to select a roller chain with a sufficient load capacity for the specific lifting application. Factors such as the weight of the load, acceleration, and dynamic forces should be considered to ensure the chain can handle the load without excessive stress.

2. Safety Measures: Vertical lifting applications require appropriate safety measures to prevent accidents or chain failure. These may include the use of safety devices such as overload protection mechanisms, emergency stops, and redundant systems. Safety standards and regulations specific to the lifting industry should be followed to ensure compliance and mitigate potential hazards.

3. Lubrication and Maintenance: Proper lubrication is critical for the smooth and reliable operation of roller chains in any application, including vertical lifting. Regular lubrication and maintenance help reduce wear, friction, and the risk of chain failure. It is important to follow the manufacturer’s recommendations for lubrication intervals and use the appropriate lubricant for the specific operating conditions.

4. Chain Tension: Maintaining proper chain tension is crucial for the safe and efficient operation of roller chains in vertical lifting applications. Adequate tension ensures proper engagement with the sprockets and minimizes the risk of chain slippage or disengagement. Regular inspection and adjustment of chain tension are necessary to ensure reliable performance.

While roller chains can be used for vertical lifting, it is important to consult with industry experts or engineers experienced in lifting applications to determine the suitability of roller chains for a specific vertical lifting task. They can provide guidance on selecting the appropriate chain size, design, and safety measures to ensure the lifting operation is safe, efficient, and compliant with applicable regulations.

editor by CX 2023-09-21

China factory CZPT Customized Roller Chain Coupling, Chain Coupling for Chain Mortising Machine

Product Description

Densen customized roller chain coupling,chain coupling for chain mortising machine

We have professionals to solve your questions, please contact us directly!

| Product Name | Densen customized roller chain coupling,chain coupling for chain mortising machine |

| DN mm | 16~190mm |

| Rated Torque | 40~25000 N·m |

| Allowable speed | 4500~200 kN·m |

| Material | 45#steel |

| Application | Widely used in metallurgy, mining, engineering and other fields. |

Product show

Company Information

Equipment

Application Case

Typical case of diaphragm coupling applied to variable frequency speed control equipment

JMB type coupling is applied to HangZhou Oilfield Thermal Power Plant

According to the requirements of HangZhou Electric Power Corporation, HangZhou Oilfield Thermal Power Plant should dynamically adjust the power generation according to the load of the power grid and market demand, and carry out the transformation of the frequency converter and the suction fan. The motor was originally a 1600KW, 730RPM non-frequency variable speed motor matched by HangZhou Motor Factory. The speed control mode after changing the frequency is manual control. Press the button speed to increase 10RPM or drop 10RPM. The coupling is still the original elastic decoupling coupling, and the elastic de-coupling coupling after frequency conversion is frequently damaged, which directly affects the normal power generation.

It is found through analysis that in the process of frequency conversion speed regulation, the pin of the coupling can not bear the inertia of the speed regulation process (the diameter of the fan impeller is 3.3 meters) and is cut off, which has great damage to the motor and the fan.

Later, they switched to the JMB460 double-diaphragm wheel-type coupling of our factory (patent number: ZL.99246247.9). After 1 hour of destructive experiment and more than 1 year of operation test, the equipment is running very well, and there is no Replace the diaphragm. 12 units have been rebuilt and the operation is in good condition.

Other Application Case

Spare parts

Packaging & Shipping

Contact us

Can chain couplings accommodate parallel misalignment?

Yes, chain couplings are designed to accommodate a certain degree of parallel misalignment between the connected shafts. Parallel misalignment refers to the situation where the axes of the two shafts are not perfectly aligned and run parallel to each other but at a distance.

Chain couplings have some inherent flexibility that allows them to tolerate a certain amount of parallel misalignment. The flexibility is primarily provided by the roller chain, which can compensate for small parallel displacements between the shafts. This flexibility helps to reduce stress on the coupling components and allows for smooth operation even in the presence of parallel misalignment.

However, it is important to note that chain couplings have limitations in terms of parallel misalignment. Excessive parallel misalignment beyond the specified limits can lead to increased stress, uneven load distribution, accelerated wear, and potential coupling failure. The manufacturer’s specifications and guidelines should be followed to ensure that the parallel misalignment remains within the acceptable range for the specific chain coupling being used.

Proper alignment during installation is crucial to minimize parallel misalignment. The shafts should be aligned as closely as possible to ensure optimal performance and longevity of the chain coupling and the connected machinery or equipment. In some cases, additional measures such as shims or adjustable mounts may be necessary to achieve the desired alignment.

Regular inspection and maintenance of the chain coupling are also important to identify and address any parallel misalignment issues that may arise over time. If significant parallel misalignment is detected, corrective measures should be taken to realign the shafts or consider alternative coupling options that are better suited for parallel misalignment requirements.

In summary, chain couplings can accommodate a certain degree of parallel misalignment, but excessive misalignment should be avoided. Proper alignment during installation and adherence to manufacturer’s guidelines are essential for ensuring optimal performance, reliability, and longevity of the chain coupling and the connected machinery or equipment.

How does misalignment affect chain couplings?

Misalignment in chain couplings can have detrimental effects on their performance and lifespan. Here are some ways in which misalignment can affect chain couplings:

- Increase in Load: Misalignment puts additional load on the coupling components. When the shafts connected by the coupling are not properly aligned, the coupling must compensate for the angular, parallel, or axial misalignment. This increased load can lead to excessive stress and premature wear on the coupling components, such as sprockets, roller chain, and connecting pins.

- Uneven Load Distribution: Misalignment can cause an uneven distribution of load across the coupling. As a result, some sections of the coupling experience higher stresses than others. This uneven load distribution can lead to localized wear and fatigue, reducing the overall strength and reliability of the coupling.

- Reduced Power Transmission: Misalignment affects the efficiency of power transmission through the coupling. When the shafts are not properly aligned, there is increased friction and slippage between the roller chain and the sprockets. This slippage reduces the amount of power transferred from one shaft to another, resulting in a loss of efficiency and a decrease in the overall performance of the machinery or equipment.

- Increased Wear: Misalignment can accelerate wear on the coupling components. The misalignment causes the roller chain to operate at an angle or with excessive tension, causing additional stress and wear on the chain links, sprocket teeth, and connecting pins. The increased wear can lead to chain elongation, loss of engagement with the sprockets, and ultimately, coupling failure.

- Noise and Vibration: Misalignment often results in increased noise and vibration during operation. The misaligned coupling generates additional vibrations and impacts, leading to excessive noise and potential damage to the coupling and surrounding equipment. These vibrations can also propagate through the connected machinery, affecting its overall performance and reliability.

To mitigate the negative effects of misalignment, it is crucial to ensure proper alignment of the shafts and the chain coupling during installation and periodically check and adjust the alignment as needed. Proper alignment minimizes stress on the coupling components, maximizes power transmission efficiency, and extends the service life of the chain coupling.

How does a chain coupling work?

A chain coupling works by connecting two rotating shafts using a roller chain and sprockets. The sprockets have teeth that engage with the rollers of the chain, creating a positive drive mechanism.

When the first shaft rotates, it drives the sprocket attached to it. The engaged chain then transfers the motion to the second sprocket and the second shaft, causing it to rotate as well.

The chain coupling design allows for flexibility and misalignment compensation. In the presence of angular misalignment between the shafts, the chain can accommodate the deviation by flexing and adjusting its position on the sprockets. Similarly, if there is parallel misalignment or axial displacement, the chain coupling can flex and adjust to maintain proper engagement and transmit torque between the shafts.

The engagement between the sprocket teeth and the chain rollers ensures a positive drive, meaning that the torque from the driving shaft is efficiently transferred to the driven shaft. This makes chain couplings suitable for applications where high torque loads need to be transmitted.

Proper lubrication is essential for the smooth operation and longevity of a chain coupling. Lubricants such as oil or grease are applied to the chain and sprockets to reduce friction and wear. The lubrication helps prevent heat buildup and ensures the chain and sprockets rotate smoothly, minimizing power losses and extending the lifespan of the coupling.

In summary, a chain coupling operates by using a roller chain and sprockets to connect two rotating shafts. The engaged chain transfers torque from the driving shaft to the driven shaft, while accommodating misalignment between the shafts. The positive drive mechanism and the flexibility of the chain make chain couplings effective in transmitting high torque loads while allowing for smooth and reliable power transmission.

editor by CX 2023-09-12

China manufacturer CZPT Customized Roller Chain Coupling, Chain Coupling for Chain Mortising Machine

Product Description

Densen customized roller chain coupling,chain coupling for chain mortising machine

We have professionals to solve your questions, please contact us directly!

| Product Name | Densen customized roller chain coupling,chain coupling for chain mortising machine |

| DN mm | 16~190mm |

| Rated Torque | 40~25000 N·m |

| Allowable speed | 4500~200 kN·m |

| Material | 45#steel |

| Application | Widely used in metallurgy, mining, engineering and other fields. |

Product show

Company Information

Equipment

Application Case

Typical case of diaphragm coupling applied to variable frequency speed control equipment

JMB type coupling is applied to HangZhou Oilfield Thermal Power Plant

According to the requirements of HangZhou Electric Power Corporation, HangZhou Oilfield Thermal Power Plant should dynamically adjust the power generation according to the load of the power grid and market demand, and carry out the transformation of the frequency converter and the suction fan. The motor was originally a 1600KW, 730RPM non-frequency variable speed motor matched by HangZhou Motor Factory. The speed control mode after changing the frequency is manual control. Press the button speed to increase 10RPM or drop 10RPM. The coupling is still the original elastic decoupling coupling, and the elastic de-coupling coupling after frequency conversion is frequently damaged, which directly affects the normal power generation.

It is found through analysis that in the process of frequency conversion speed regulation, the pin of the coupling can not bear the inertia of the speed regulation process (the diameter of the fan impeller is 3.3 meters) and is cut off, which has great damage to the motor and the fan.

Later, they switched to the JMB460 double-diaphragm wheel-type coupling of our factory (patent number: ZL.99246247.9). After 1 hour of destructive experiment and more than 1 year of operation test, the equipment is running very well, and there is no Replace the diaphragm. 12 units have been rebuilt and the operation is in good condition.

Other Application Case

Spare parts

Packaging & Shipping

Contact us

Can chain couplings accommodate parallel misalignment?

Yes, chain couplings are designed to accommodate a certain degree of parallel misalignment between the connected shafts. Parallel misalignment refers to the situation where the axes of the two shafts are not perfectly aligned and run parallel to each other but at a distance.

Chain couplings have some inherent flexibility that allows them to tolerate a certain amount of parallel misalignment. The flexibility is primarily provided by the roller chain, which can compensate for small parallel displacements between the shafts. This flexibility helps to reduce stress on the coupling components and allows for smooth operation even in the presence of parallel misalignment.

However, it is important to note that chain couplings have limitations in terms of parallel misalignment. Excessive parallel misalignment beyond the specified limits can lead to increased stress, uneven load distribution, accelerated wear, and potential coupling failure. The manufacturer’s specifications and guidelines should be followed to ensure that the parallel misalignment remains within the acceptable range for the specific chain coupling being used.

Proper alignment during installation is crucial to minimize parallel misalignment. The shafts should be aligned as closely as possible to ensure optimal performance and longevity of the chain coupling and the connected machinery or equipment. In some cases, additional measures such as shims or adjustable mounts may be necessary to achieve the desired alignment.

Regular inspection and maintenance of the chain coupling are also important to identify and address any parallel misalignment issues that may arise over time. If significant parallel misalignment is detected, corrective measures should be taken to realign the shafts or consider alternative coupling options that are better suited for parallel misalignment requirements.

In summary, chain couplings can accommodate a certain degree of parallel misalignment, but excessive misalignment should be avoided. Proper alignment during installation and adherence to manufacturer’s guidelines are essential for ensuring optimal performance, reliability, and longevity of the chain coupling and the connected machinery or equipment.

What are the key components of a chain coupling?

A chain coupling consists of several key components that work together to transmit power and accommodate misalignments. Here are the main components of a chain coupling:

- Sprockets: Sprockets are the toothed wheels that engage with the chain. They are typically made of steel or other durable materials and have specially designed teeth that mesh with the chain rollers. The sprockets provide the driving and driven connections, transmitting torque from one shaft to another.

- Roller Chain: The roller chain is a series of interconnected links with rollers between them. It is looped around the sprockets, with the rollers engaging with the sprocket teeth. The roller chain transfers the rotational motion from the driving sprocket to the driven sprocket, allowing power transmission between the shafts.

- Connecting Pins: Connecting pins are used to join the links of the roller chain together, forming a continuous loop. These pins are inserted through the pin holes in the chain links and secured with retaining clips or other fasteners. They ensure the integrity and strength of the chain.

- Bushings or Bearings: Bushings or bearings are used to support the shafts and allow them to rotate smoothly within the chain coupling. They are typically inserted into the bores of the sprockets and provide a low-friction interface between the shaft and the coupling components.

- Guard or Cover: In some chain couplings, a guard or cover is added to enclose the sprockets and chain. This serves as a protective barrier, preventing contact with moving parts and reducing the risk of accidents or injuries. The guard or cover also helps to contain lubrication and protect the chain from contaminants.

- Lubrication: Lubrication is essential for the smooth operation and longevity of a chain coupling. Proper lubrication reduces friction, wear, and noise. Lubricants, such as chain oil or grease, are applied to the chain and sprockets to minimize frictional losses and prevent premature wear.

These components work together to provide a reliable and efficient power transmission in chain couplings. The sprockets engage with the roller chain, and as one sprocket rotates, it drives the chain, causing the other sprocket and the connected shaft to rotate. The roller chain and its components, along with lubrication, allow for flexibility and compensation of misalignment between the shafts.

How does a chain coupling work?

A chain coupling works by connecting two rotating shafts using a roller chain and sprockets. The sprockets have teeth that engage with the rollers of the chain, creating a positive drive mechanism.

When the first shaft rotates, it drives the sprocket attached to it. The engaged chain then transfers the motion to the second sprocket and the second shaft, causing it to rotate as well.

The chain coupling design allows for flexibility and misalignment compensation. In the presence of angular misalignment between the shafts, the chain can accommodate the deviation by flexing and adjusting its position on the sprockets. Similarly, if there is parallel misalignment or axial displacement, the chain coupling can flex and adjust to maintain proper engagement and transmit torque between the shafts.

The engagement between the sprocket teeth and the chain rollers ensures a positive drive, meaning that the torque from the driving shaft is efficiently transferred to the driven shaft. This makes chain couplings suitable for applications where high torque loads need to be transmitted.

Proper lubrication is essential for the smooth operation and longevity of a chain coupling. Lubricants such as oil or grease are applied to the chain and sprockets to reduce friction and wear. The lubrication helps prevent heat buildup and ensures the chain and sprockets rotate smoothly, minimizing power losses and extending the lifespan of the coupling.

In summary, a chain coupling operates by using a roller chain and sprockets to connect two rotating shafts. The engaged chain transfers torque from the driving shaft to the driven shaft, while accommodating misalignment between the shafts. The positive drive mechanism and the flexibility of the chain make chain couplings effective in transmitting high torque loads while allowing for smooth and reliable power transmission.

editor by CX 2023-09-04

China Professional Kc Series Steel Roller Chain Flexible Couplings for Paper Bag Machine New

Product Description

Product Description

Detailed Photos

Certifications

Company Profile

FAQ

Q: Are you a trading company or manufacturer?

A: We’re factory and providing gearbox ODM & OEM services for the European market for more than 10 years

Q: Do you provide samples? is it free or extra?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: How long is your delivery time? What is your terms of payment?

A: Generally it is 40-45 days. The time may vary depending on the product and the level of customization.

For standard products, the payment is: 30% T/T in advance,balance before shipment.

Q: What is the exact MOQ or price for your product?

A: As an OEM company, we can provide and adapt our products to a wide range of needs.

Thus, MOQ and price may greatly vary with size, material and further specifications; For instance, costly products or standard products will usually have a lower MOQ. Please contact us with all relevant details to get the most accurate quotation.

If you have another question, please feel free to contact us.

Comparison of Roller Chain Couplings to Other Coupling Types

Roller chain couplings offer distinct advantages and characteristics that set them apart from other coupling types, such as gear or disc couplings. Below is a comparison of roller chain couplings with these two commonly used coupling types:

- Roller Chain Couplings:

– Roller chain couplings are flexible and can accommodate misalignments, making them ideal for applications where shafts may not be perfectly aligned.

– They offer good shock absorption, which is beneficial in systems with varying loads or frequent starts and stops.

– Roller chain couplings are relatively compact and lightweight compared to other couplings, making them suitable for space-constrained installations.

– These couplings are cost-effective and provide a reliable and efficient power transmission solution.

- Gear Couplings:

– Gear couplings are capable of handling high torque and can transmit power efficiently, making them suitable for heavy-duty applications.

– They have a high level of torsional rigidity, ensuring accurate torque transmission without backlash.

– Gear couplings are generally more expensive than roller chain couplings.

– They require accurate alignment during installation, which can be challenging in some applications.

- Disc Couplings:

– Disc couplings offer high torque capacity and torsional stiffness, providing precise torque transmission and no backlash.

– They have a compact design and are often used in applications with limited space.

– Disc couplings can handle misalignment to some extent but may not be as forgiving as roller chain couplings.

– They are generally more expensive than roller chain couplings.

When choosing the appropriate coupling type, it is essential to consider the specific requirements of the application, such as torque, misalignment, speed, space limitations, and budget constraints. Each coupling type has its strengths, and the selection should be based on the demands of the mechanical power transmission system.

Maintenance Requirements for Roller Chain Couplings

To ensure the optimal performance and longevity of roller chain couplings, regular maintenance is essential. Here are some key maintenance requirements:

- Lubrication: Regularly lubricate the roller chain and sprockets to reduce friction and wear. Use the appropriate lubricant recommended by the coupling manufacturer.

- Inspections: Periodically inspect the coupling for signs of wear, misalignment, or damage. Look for elongation or wear of the roller chain, damaged sprocket teeth, or any signs of excessive vibration.

- Tightening: Check and ensure that all fasteners, such as bolts and set screws, are properly tightened to the manufacturer’s recommended torque specifications.

- Alignment: Maintain proper alignment between the driving and driven shafts to prevent undue stress on the coupling components.

- Cleanliness: Keep the coupling and surrounding area clean and free from debris or contaminants that could interfere with its operation.

- Temperature: Avoid operating the coupling beyond its recommended temperature limits, as excessive heat can lead to premature failure.

- Replacement: Replace any worn or damaged components promptly to prevent further damage to the coupling or connected equipment.

Regular maintenance not only ensures the coupling’s optimal performance but also helps identify potential issues early, allowing for timely repairs or replacements. It is crucial to follow the manufacturer’s maintenance guidelines and schedule to ensure the coupling’s reliability and prevent unexpected failures that could disrupt operations and lead to costly downtime.

Working Principle of Roller Chain Coupling and Its Advantages

A roller chain coupling works on the principle of transferring torque between two shafts using a roller chain wrapped around sprockets on each shaft. The sprockets are connected by the roller chain, and when one sprocket rotates, it drives the other sprocket, transmitting the torque from one shaft to the other.

The advantages of roller chain couplings over other coupling types include:

- High Torque Capacity: Roller chain couplings can handle high torque loads, making them suitable for heavy-duty industrial applications.

- Compact Design: The compact and simple design of roller chain couplings allows for easy installation in tight spaces and restricted environments.

- Misalignment Tolerance: Roller chain couplings can accommodate angular, parallel, and axial misalignments between the shafts, reducing the need for precise alignment during installation.

- Shock Absorption: The inherent flexibility of the roller chain allows it to absorb shocks and dampen vibrations, protecting connected equipment from sudden loads and impacts.

- Cost-Effective: Roller chain couplings are generally cost-effective compared to other coupling types, providing an economical solution for power transmission needs.

- Wide Application Range: Roller chain couplings are used in various industries, including manufacturing, agriculture, construction, and material handling, due to their versatility and reliable performance.

- Easy Maintenance: Roller chain couplings are relatively easy to maintain and require minimal lubrication to keep the chain running smoothly.

- Long Service Life: When properly installed and maintained, roller chain couplings offer a long service life, contributing to the overall efficiency and reliability of mechanical systems.

Overall, the working principle and advantages of roller chain couplings make them a popular choice for transmitting torque between shafts in diverse industrial applications.

editor by CX 2023-08-09

Best made in China – replacement parts – pintle Chain & sprocket manufacturer : Machine drive bc chain up China in Ndola Zambia Roller Chain for Conveyor Industries with ce certificate top quality low price

We – EPG Team the greatest Chain and agricultural gearbox factory in China with 5 diverse branches. For a lot more specifics: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

EPG will often adhere to it business spirit of getting practical, modern, successful and outstanding to make the best intercontinental transmission push.We’ve Maintaining in mind that very good provider is the key to cooperating with customers, we attempt to meet higher high quality requirements, supply aggressive costs and make sure prompt supply. constructed up our solution variety to respond to the vastly different problems located in different industrial environments close to the entire world. From large business to precision production, we work with conclude-users in almost each industry and have specialist options which are established to provide a distinct overall performance gain for your software. ISO 9001:2000 & AS 9100B accredited custom manufacturer of roller chains. Requirements of roller chains contain .1475 in. to .3750 in. pitch, 5.9 in. to 35.4 in. length, one hundred eighty lbs. to 1529 lbs. tensile load ability & .035 lbs. to .276 lbs. excess weight/ft. We EPT Device firm are one particular specialist sector rollor chain factory, We have stamping, warmth treatment, sorting, synthesis and EPT innovative manufacturing tools. Our company offers numerous massive precision superior equipments, mordern methods for cess and precision devices, so as to insure the very good quality of our rollor chains. Our rollor chains are widely utilised in bike, blend harvester, metallurgical machinery, mining tools, automated manufacturing line. We are the be EPT suppliers of Chinese massive EPT palletizing robot enterprises. And exchange Japan, ZheJiang exported to Europe, The us, Asia and EPT nations and regions.

| Chain Title | Custom P100 Roller Chain For EPT Industries |

| Chain Sort | Double Pitch Chain, EPT Chain |

| Material | 40Mn, carbon metal |

| Pitch | 100mm |

| Roller Diameter | 38mm |

| Pin Diameter | 10 |

| Plate Thickness | 4mm |

Manufacturing Equipment

Goods Show

Bundle & Shipping

Enable us function with each other to make acquire-acquire profits!

The use of original equipment manufacturer’s (OEM) element numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating solution use and compatibility. Our organization and the detailed substitution components contained herein are not sponsored, accepted, or made by the OEM.

Best made in China – replacement parts – roller blind chain joining link bunnings China in Celaya Mexico Buy Hot Film Shrink Wrapping Machine with ce certificate top quality low price

We – EPG Group the most significant Chain and agricultural gearbox manufacturing unit in China with 5 different branches. For far more specifics: Cell/whatsapp/telegram/Kakao us at: 0086-13083988828

EPG is a single of the most significant producers in China. We have superior devices for manufacturing and new technologies testing capacity . Via adopting new technology from British, German, U.S.A, our goods are very best sellers all more than European, The usa, and Southeast Asia.ISO specialize in power transmission goods Chain,pto shaft, agricultural gearboxes , CATV goods, mechanical seal, hydraulic and Pheumatic, and marketing items.9001 accredited company of precision roller chains. Types consist of one and multiple strand, hollow pin, facet bow, rollerless, self-lubricating, straight sidebar, double pitch, brushed, nickel plated, armor coated, 304 stainless metal, leaf, hoist and O-ring, citrus, sorting and caterpillar roller chains. ISO 9001:2000 & AS 9100B qualified personalized maker of roller chains. Technical specs of roller chains contain .1475 in. to .3750 in. pitch, 5.9 in. to 35.4 in. length, 180 lbs. to 1529 lbs. tensile load capacity & .035 lbs. to .276 lbs. excess weight/ft. Description:

Lovely equipment, Steady quality, Security,energy saving, patented products, domestic initiative, software to the POF PVC PP movie thermal shrink packaging impact is excellent.

Features:

one.Appearance and knot style in accordance with nationwide stHangZhourds, the fuselage uses fingerprint resistant sheet production right after spray remedy.

2.Manage panel employing programming technique, 12V DC input , button change , electronic show.

3. Transmission utilizing 24v DC Motor pace manage making use of variable frequency engineering -9 file adjustment.

four.The conveyor belt can be employed wire mesh belt, chain roller, Teflon mesh belt a few.

five.Heating utilizing 600W 220V considerably infrared quartz heating tube.

six.Temperature handle employing large precision intelligent temperature control technique . up and down temperature independent regulation.

seven.Sizzling air circulation using 220V 60W 2200 to the extended axis motor with wind wheel.

8.The bracket can be disassembled , and the peak of the bracket can be adjusted.

| L SEALER | FQL 450 A | SHRINK TUNNEL | BSN 4571C |

| VOLTAGE | 220/50-60HZ | VOLTAGE | 380v fifty-60HZ |

| Electrical power | 1.35KW | Energy | 9KW |

| AIR Strain: | 5-7 | TUNNEL Size(L*W*H) | 1200*400x200mm |

| Ability | fifteen-30bags/min | Solution Dimensions(W*H) | 350x150mm |

| Solution MAX SIZE L+H(H<150mm) | <500mm | EPT Speed | -15m/min |

| Solution MAX Dimensions W+H(H<150mm) | < 400mm | Materials | CHAIN, TEFLON |

| SEALING Measurement | 550*450mm | CONVEYING LOAD | 20kg max |

| Device Dimensions (L*W*H) | 1650*800*1450mm | Equipment Size (L*W*H) | 1600x560x660mm |

| Fat | 300KG | Weight | 80kg |

| Software: | POF.PE, | Software: | PE.POF |

The use of original products manufacturer’s (OEM) portion numbers or trademarks , e.g. CASE® and John Deere® are for reference needs only and for indicating merchandise use and compatibility. Our organization and the detailed substitution elements contained herein are not sponsored, accredited, or created by the OEM.