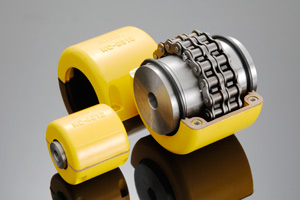

Introducing Roller Chain Coupling for Bridge Construction

When it comes to bridge construction, roller chain couplings play a crucial role in ensuring the smooth and efficient operation of various machinery and equipment. Here are five key points to consider:

1. Durability

Roller chain couplings are known for their durability, making them ideal for heavy-duty applications such as bridge construction. They can withstand high torque loads and harsh environmental conditions, ensuring reliable performance.

2. Flexibility

These couplings offer flexibility in terms of alignment and installation, making them easy to integrate into different systems. This flexibility is essential in bridge construction projects where precision and adaptability are key.

3. Maintenance

Roller chain couplings require minimal maintenance, reducing downtime and ensuring continuous operation. This is crucial for bridge construction projects where any delays can have significant consequences.

4. Cost-Effectiveness

Despite their high performance and durability, roller chain couplings are cost-effective compared to other coupling options. This makes them a practical choice for bridge construction projects that require reliable and efficient equipment.

5. Safety

Roller chain couplings are designed with safety in mind, providing secure connections between machinery components. This helps prevent accidents and ensures the safety of workers involved in bridge construction.

What is a Roller Chain Coupling?

Roller chain coupling is a type of mechanical device used to connect two shafts together for transmitting power. Here are five aspects to consider:

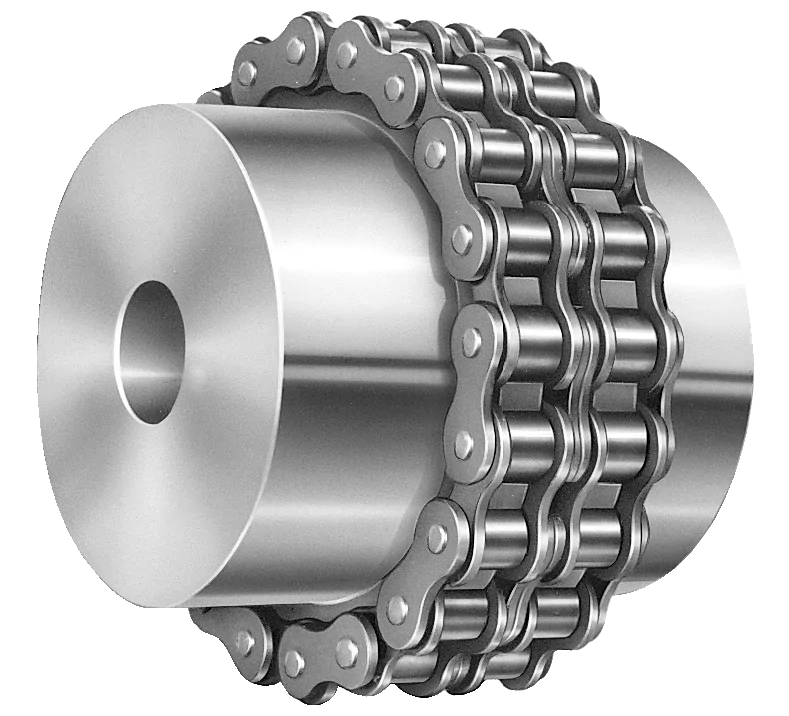

1. Construction

Roller chain couplings consist of two sprockets connected by a roller chain, allowing for the transmission of power between two shafts. This design ensures efficient power transfer and reliable operation.

2. Functionality

These couplings are designed to accommodate misalignment between shafts, reducing wear and tear on machinery components. They also dampen vibrations and shock loads, improving overall system performance.

3. Applications

Roller chain couplings are commonly used in various industries, including bridge construction, where reliable power transmission is essential. They are versatile and can be customized to suit specific project requirements.

4. Benefits

One of the key advantages of roller chain couplings is their high torque capacity, making them suitable for heavy-duty applications. They are also easy to install and maintain, saving time and resources in the long run.

5. Considerations

When choosing a roller chain coupling, factors such as load capacity, speed, and environmental conditions should be taken into account to ensure optimal performance and longevity.

What are the Advantages of Roller Chain Coupling?

Roller chain couplings offer several advantages that make them a popular choice for various applications. Here are five key aspects to consider:

1. High Torque Capacity

Roller chain couplings can handle high torque loads, making them suitable for heavy-duty applications where power transmission is critical. This ensures reliable performance and durability.

2. Easy Installation

These couplings are easy to install and require minimal maintenance, reducing downtime and ensuring continuous operation. This makes them a cost-effective solution for various industries.

3. Durable Construction

Roller chain couplings are built to last, with sturdy materials and precision engineering ensuring long-term reliability. This durability reduces the need for frequent replacements, saving time and resources.

4. Versatility

These couplings are versatile and can be customized to suit specific project requirements. They are available in various sizes and configurations, making them suitable for a wide range of applications.

5. Cost-Effectiveness

Despite their high performance and durability, roller chain couplings are cost-effective compared to other coupling options. This makes them a practical choice for businesses looking to optimize their operations.

Key Applications of Hydraulic Couplings

When it comes to hydraulic couplings, there are several key applications to consider:

1. Industrial Machinery

Hydraulic couplings are commonly used in industrial machinery for power transmission and control, ensuring efficient operation and performance.

2. Construction Equipment

These couplings are essential for various construction equipment, such as cranes and excavators, providing reliable power transmission and flexibility.

3. Agricultural Machinery

Hydraulic couplings play a crucial role in agricultural machinery, enabling precise control and operation in farming applications.

4. Automotive Industry

These couplings are used in the automotive industry for power steering systems, transmission systems, and other critical components.

5. Aerospace Applications

Hydraulic couplings are also utilized in aerospace applications for aircraft control systems, landing gear, and other hydraulic mechanisms.

When to Use Chain Coupling?

Chain couplings are ideal for various applications, including:

1. High Torque Loads

Chain couplings are recommended for applications with high torque loads, where reliable power transmission is essential.

2. Misalignment

These couplings can accommodate shaft misalignment, reducing wear and tear on machinery components and improving overall system performance.

3. Heavy-Duty Machinery

Chain couplings are suitable for heavy-duty machinery and equipment, where durability and efficiency are paramount.

4. Variable Speeds

These couplings can handle variable speeds and shock loads, making them versatile and adaptable to different operating conditions.

5. Precision Applications

Chain couplings are ideal for precision applications where accurate power transmission is required, ensuring smooth and reliable operation.

Which Chain Coupling is Recommended for High Torque Loads?

When it comes to high torque loads, certain chain couplings are recommended for optimal performance:

1. Roller Chain Couplings

Roller chain couplings are ideal for high torque loads, providing reliable power transmission and durability in heavy-duty applications.

2. Silent Chain Couplings

Silent chain couplings offer smooth and quiet operation, making them suitable for applications where noise levels need to be minimized.

3. Block Chain Couplings

Block chain couplings are designed for heavy-duty applications with high torque requirements, ensuring secure and efficient power transmission.

4. Steel Chain Couplings

Steel chain couplings are known for their durability and strength, making them a reliable choice for high torque loads and harsh operating conditions.

5. Drop Forged Chain Couplings

Drop forged chain couplings are built to handle extreme loads and provide long-term reliability in demanding applications where high torque is a factor.

About HZPT

At HZPT, we pride ourselves on being a leading manufacturer and exporter of couplings, with a strong focus on quality, innovation, and customer satisfaction. With over 16 years of experience in the industry, we have established ourselves as a trusted partner for businesses in Europe and the United States.

Our commitment to excellence is reflected in our comprehensive quality inspection system, which ensures that all our products meet the highest standards of performance and reliability. We have a dedicated design and R&D team that can customize products to meet the specific requirements of our global customers.

When you choose HZPT, you can expect the best service, highest product quality, and competitive prices. We offer ODM and OEM services, 24-hour customer support, and a wide range of coupling options to meet your needs. Contact us today to learn more about how we can help you with your coupling requirements.